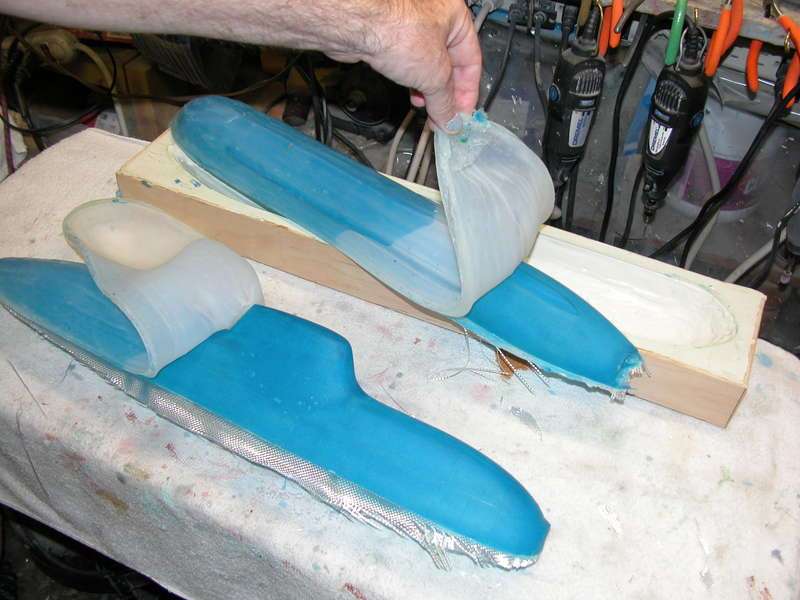

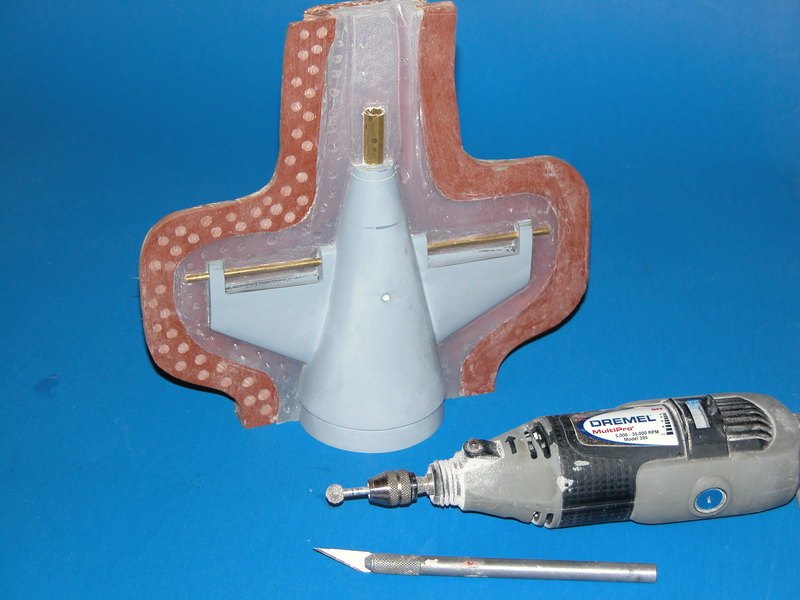

I remember reading about tools where part of the tooling was rubber, to resolve fine detail and/or relieve an undercut, and the rest a hardcase. I was looking at using this method for a couple of hulls I want to mould, part of reasoning is to reduce the amount of tool parts I'd need to effect a release, and the other is that I would like a tool where I can join the halves together in the tool if possible.

It seems most builders use a complete rubber tool or complete hardcase tool, which made me wonder if there as a few issues with the combined method?

It seems most builders use a complete rubber tool or complete hardcase tool, which made me wonder if there as a few issues with the combined method?

Comment