Or... trying to fit 10lbs of wires and connectors into a 5lb cylinder.

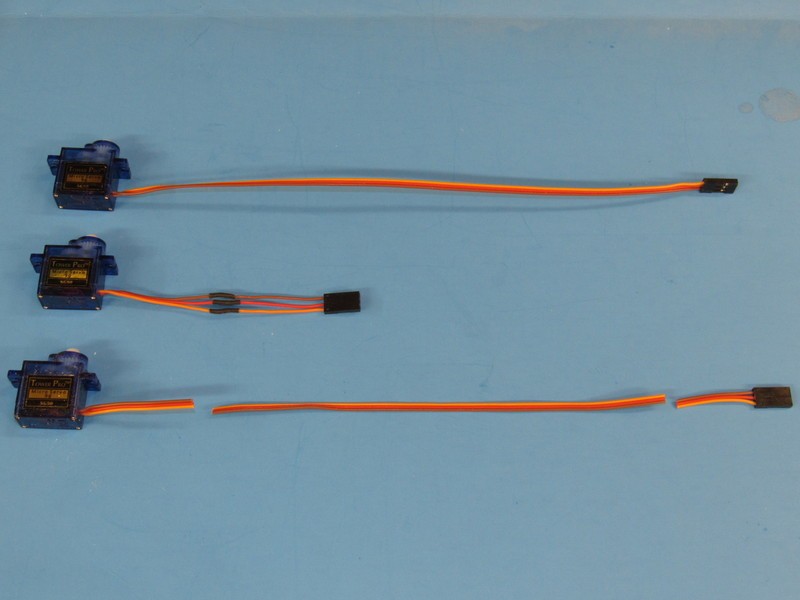

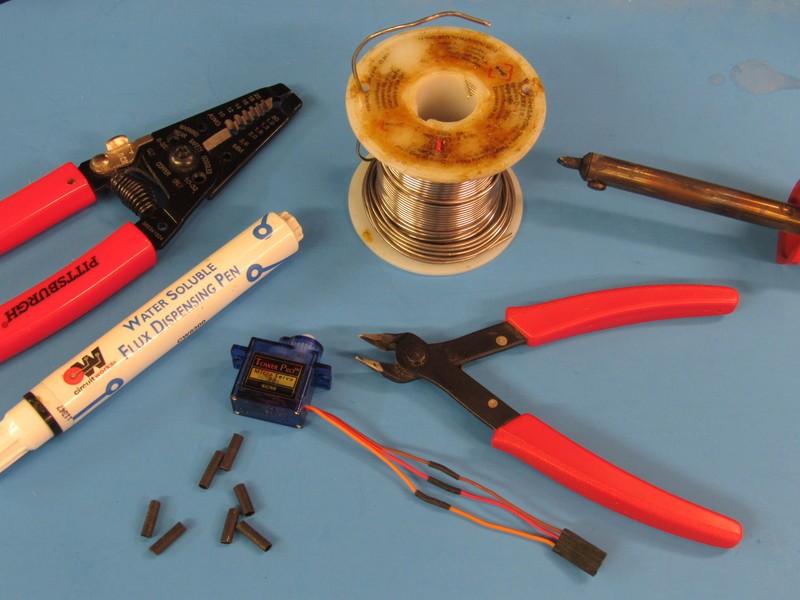

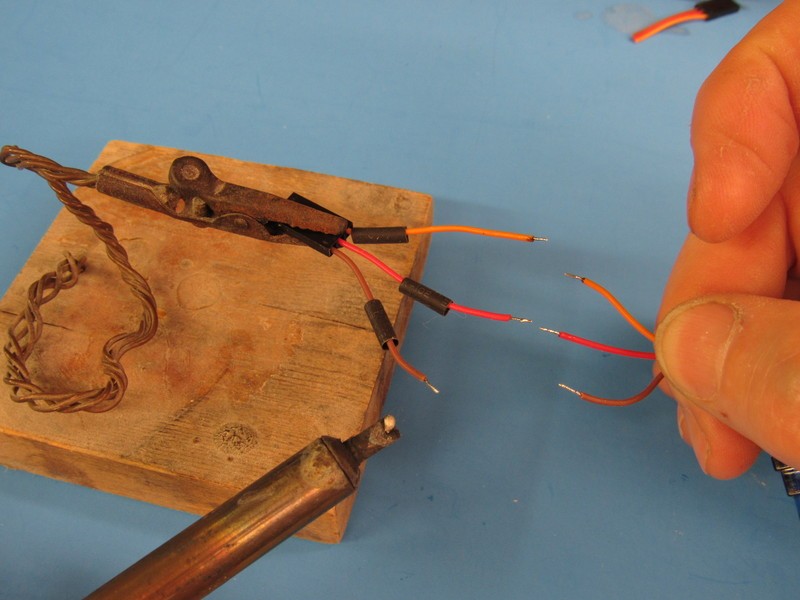

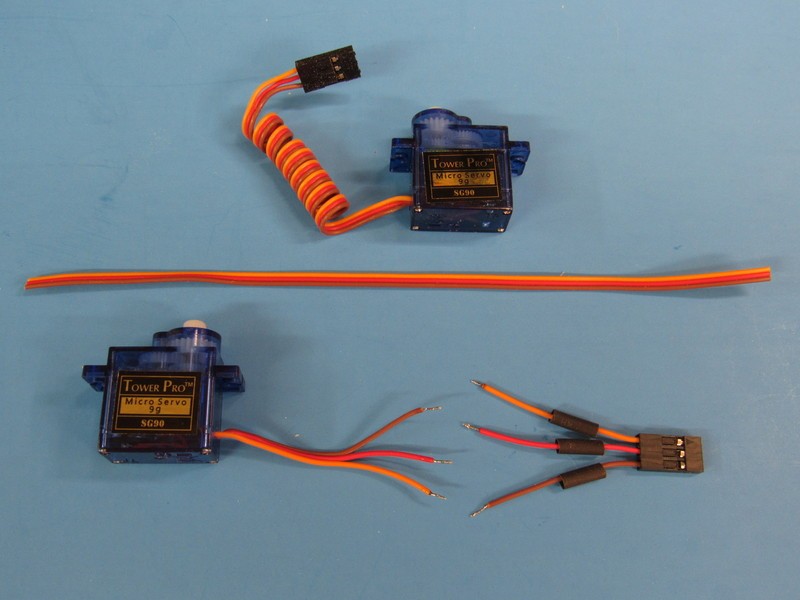

I need some help from the wise on how to jam everything into the aft dry space on my 2 inch Sub Driver. I feel like it would be appropriate to call it the machinery space... Anyway. I have tried bunching all of the wires from the servos up with mini zip-ties, but I still found myself basically cramming all of this stuff in there and thinking there has to be a better way.

So, I turn to the group. Curious to see how you all have overcome this problem of space - or a decided lack thereof.

Thank you in advance!

-Brady

I need some help from the wise on how to jam everything into the aft dry space on my 2 inch Sub Driver. I feel like it would be appropriate to call it the machinery space... Anyway. I have tried bunching all of the wires from the servos up with mini zip-ties, but I still found myself basically cramming all of this stuff in there and thinking there has to be a better way.

So, I turn to the group. Curious to see how you all have overcome this problem of space - or a decided lack thereof.

Thank you in advance!

-Brady

Comment