Anyone know if Plastruct Plastic Weld (orange label) goes bad overtime when stored after it has been opened?

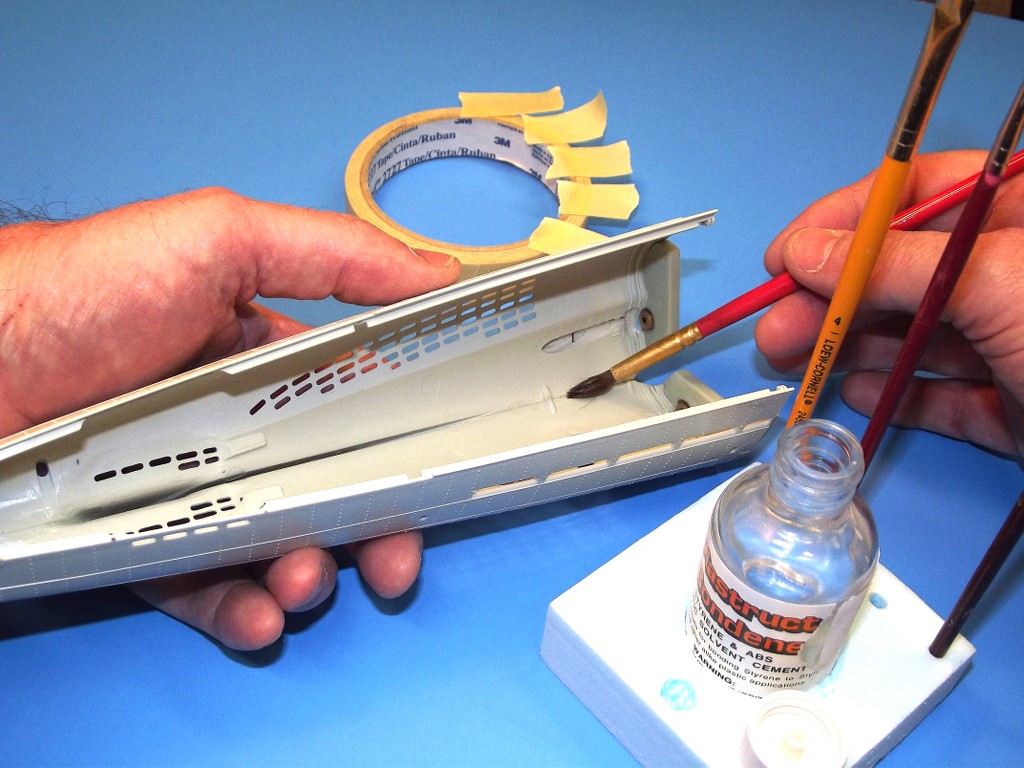

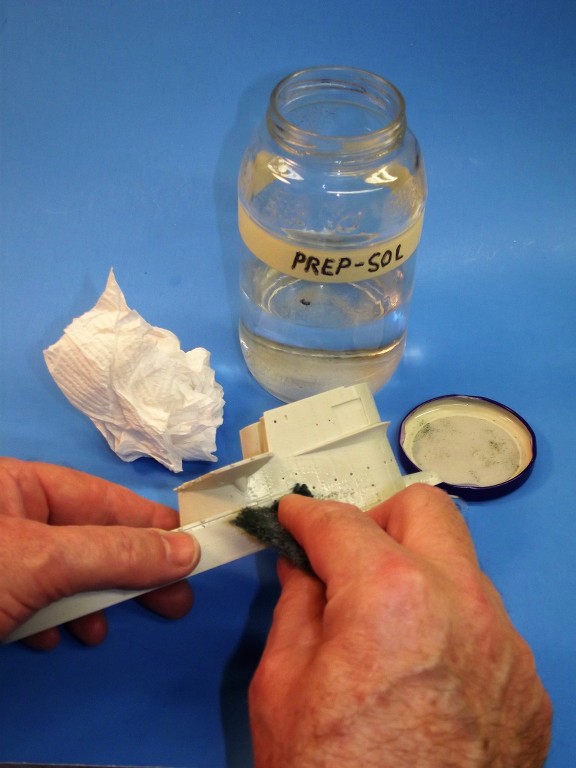

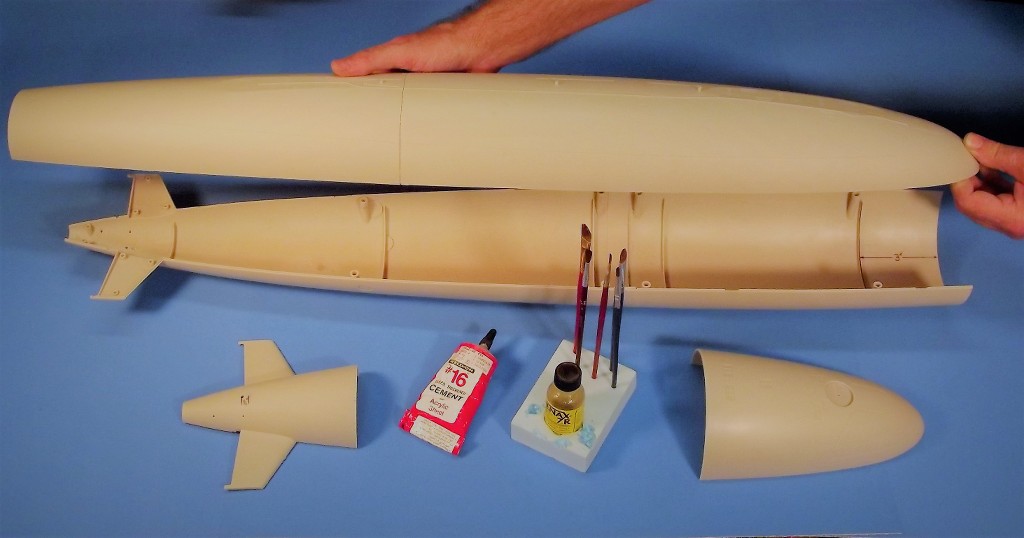

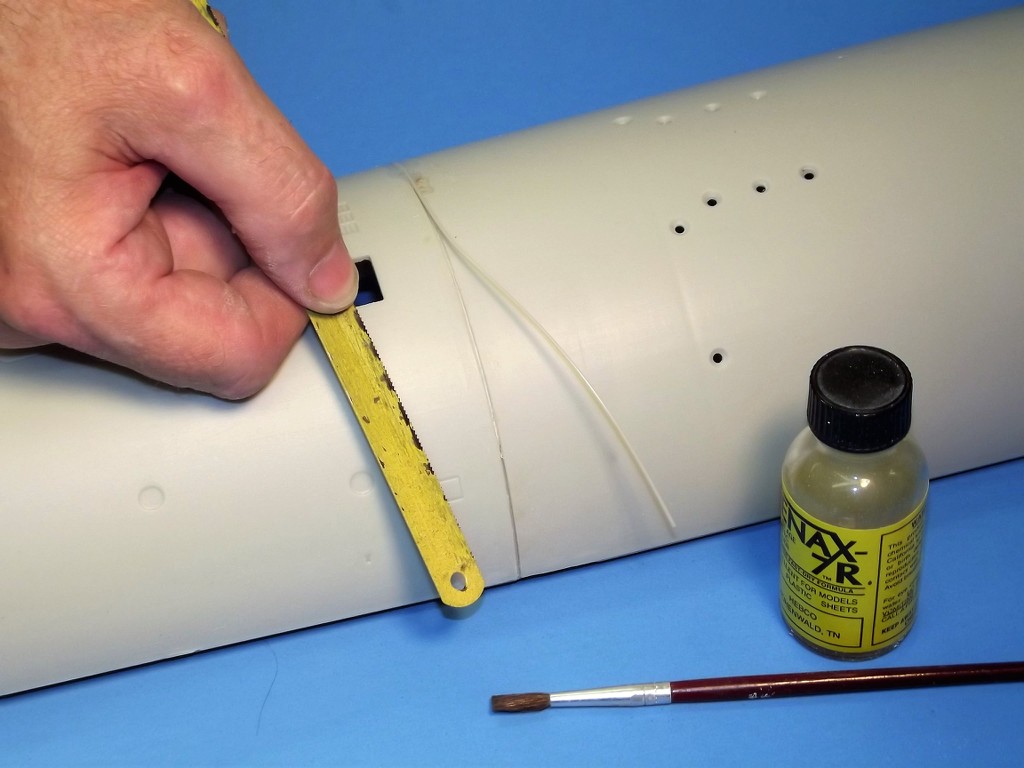

I’ve been using this stuff to bond strips of styrene to what I believe is a ABS hull(Arkmodel type VII) but the bond between the these parts has been failing fairly easily. Both parts are given a coat and held together in place while curing.

I’ve never had this problem in the past, so I’m curious if it is possible the Methyl Ethyl Ketone has lost some of its effectiveness? The bottle I have is probably 6 years old but has always been quickly resealed after each use.

I’ve been using this stuff to bond strips of styrene to what I believe is a ABS hull(Arkmodel type VII) but the bond between the these parts has been failing fairly easily. Both parts are given a coat and held together in place while curing.

I’ve never had this problem in the past, so I’m curious if it is possible the Methyl Ethyl Ketone has lost some of its effectiveness? The bottle I have is probably 6 years old but has always been quickly resealed after each use.

Comment