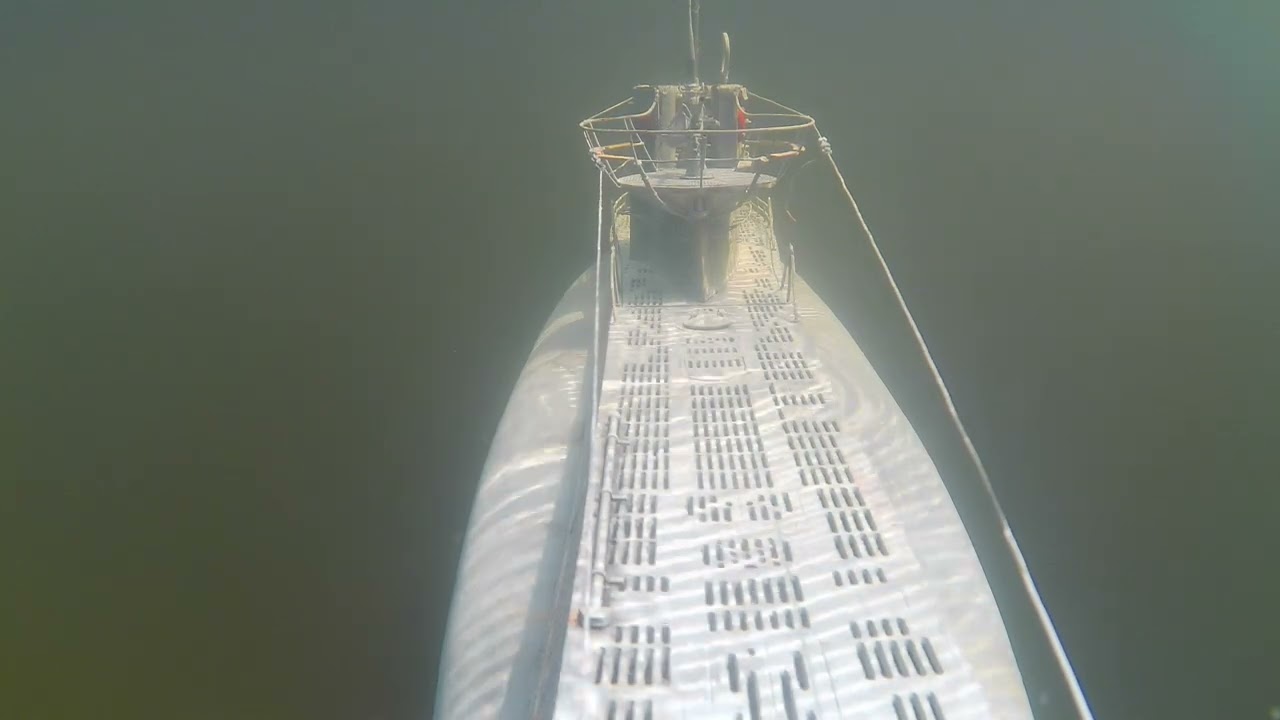

I ran my recently completed Engel VIIc for the first time (other than in the test pool) yesterday and had some interesting pros and cons.

Number 1) it has developed a leak somewhere in the stern bulkhead area that wasn't there when I checked a couple days before and will require me to take it pretty far back apart to find. One real downside of this model is when the two 750ml piston tanks fill with water it puts a significant amount of air pressure in the hull. All the seals need to be absolutely tip-top.

Number 2) My first time putting it in the water the rear piston tank would not move (fill with water). Every time I opened it up to check it worked fine, eventually I realized if I tapped on or flexed the tmax2 piston tank control board I could make it start and stop working. I loosened all the screws holding the board down and it worked the rest of the day. I suspect a bad solder joint to one of the relays but haven't looked yet.

With the tmax2 cooperating and accepting a small amount of leaking I ran the boat for a couple hours and in general It is a great running boat. With separate control of the two propellers it can turn around in its own length even when submerged, not realistic of course but useful for a model.

I eventually filmed a little bit with a go pro type camera and that is where I ran into the clearly self imposed problem number 3)

Jason.

Number 1) it has developed a leak somewhere in the stern bulkhead area that wasn't there when I checked a couple days before and will require me to take it pretty far back apart to find. One real downside of this model is when the two 750ml piston tanks fill with water it puts a significant amount of air pressure in the hull. All the seals need to be absolutely tip-top.

Number 2) My first time putting it in the water the rear piston tank would not move (fill with water). Every time I opened it up to check it worked fine, eventually I realized if I tapped on or flexed the tmax2 piston tank control board I could make it start and stop working. I loosened all the screws holding the board down and it worked the rest of the day. I suspect a bad solder joint to one of the relays but haven't looked yet.

With the tmax2 cooperating and accepting a small amount of leaking I ran the boat for a couple hours and in general It is a great running boat. With separate control of the two propellers it can turn around in its own length even when submerged, not realistic of course but useful for a model.

I eventually filmed a little bit with a go pro type camera and that is where I ran into the clearly self imposed problem number 3)

Jason.

Comment