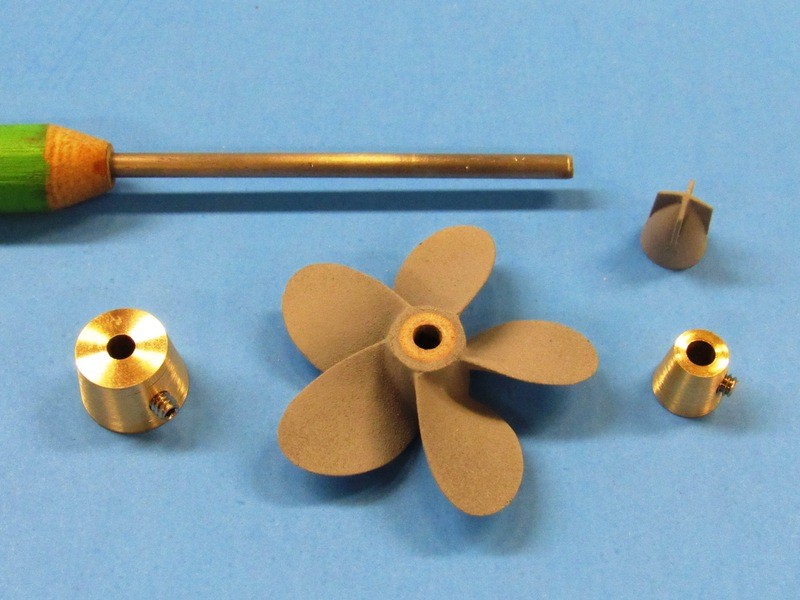

You know, I know we all say it a lot... and I know this is just another day at the office for you... but jeeeeeezus, this is some incredible **** to watch. Blows me away every single time.

Thank you for documenting it all as thoroughly as you do. Truly.

Thank you for documenting it all as thoroughly as you do. Truly.

Comment