I have used this method for 3 boats and found it to work great. I draw out the station formers in 3/4' intervals (or the thickness of the construction foam that you are using ) and include alignment and center lines at 90 degrees-it might take some extrapolation, pencil and divider work. Then they are photocopied to scale size- Minus the thickness of the fairing material (I use spackle, redlead and Bondo polyester body putty - allow 1/8") and cut out. I buy a small roll of .005" aluminum flashing at Home Depot or Lowes and using 3M 77 spray adhesive, I glue the paper formers to the flashing by only spraying one side (a tack gluing) Then the templated aluminum station formers are cut out with an ordinary scissors. Next using 3/4" construction foam (either green (Lowes) or pink (Home Depot) , I glue the formers to the foam with an alignment mark on two edges for visibility .(note that this foam cuts well with any powered saw and sands well with a belt sander (preferably bench type)...

Now I take the foam former blocks and glue them, together taking care to keep everything aligned using the marks that you drew earlier. Note that by spray gluing only one side and NOT waiting until the glue is tack free, you can pull the glued items apart if needed.

The only tool you might not have in your arsenal can be easily built , purchased or borrowed-a hot wire foam cutter.

Take the hotwire cutter and using the roof flashing as a guide, proceed to cut the hull to the desired shape.

From now on its standard body work I personally like to fair the foam out with regular spackle-it sands nicely and takes paint well. I prime and paint (Old school Rustoleum is my choice-it will withstand many solvents when fully cured) I suggest drawing in a casting line so you know where to submerge the master to, so it can be removed from the mold. If the ultracal cures over past the widest point of the hull its not coming out of the mold (if so ...chisel and hammer)

Several coats of wax and/or a parting agent and you're ready to cast 1/2 at a time ..I do 1 offs with ultracal 30 but any casting compound will work-

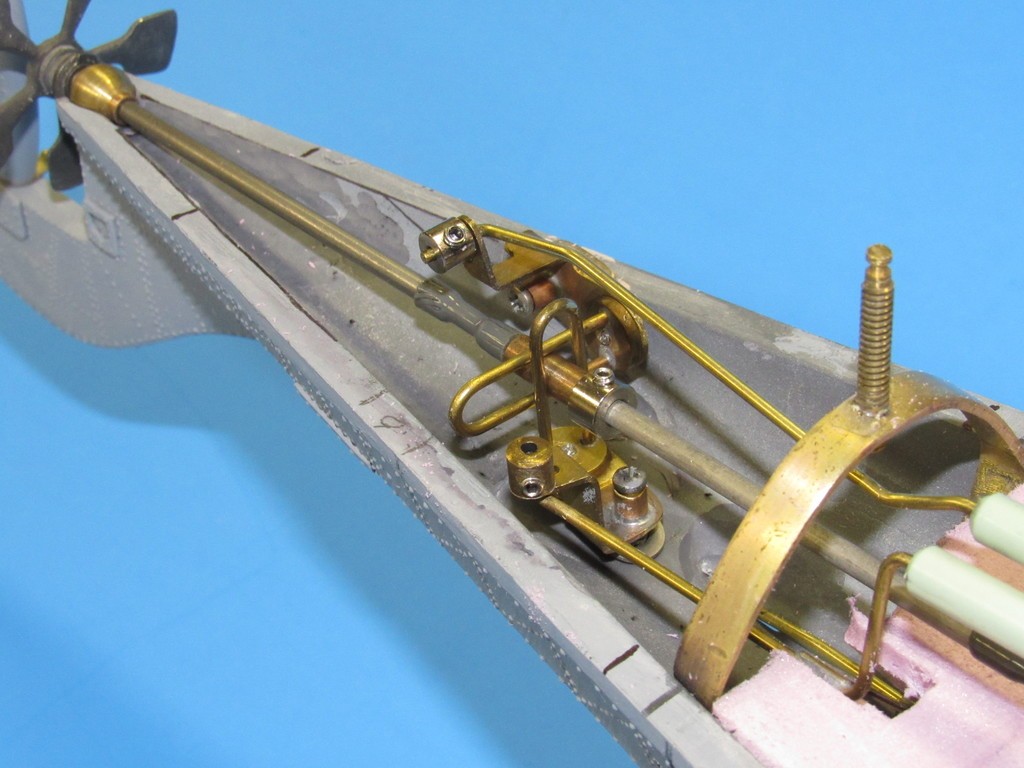

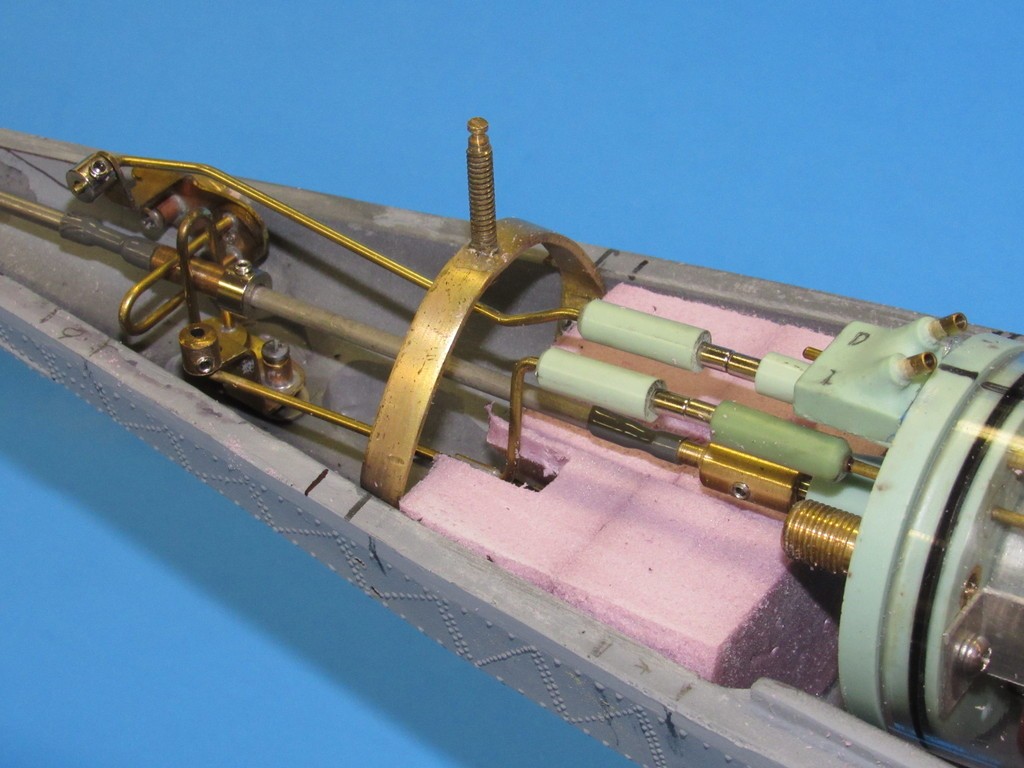

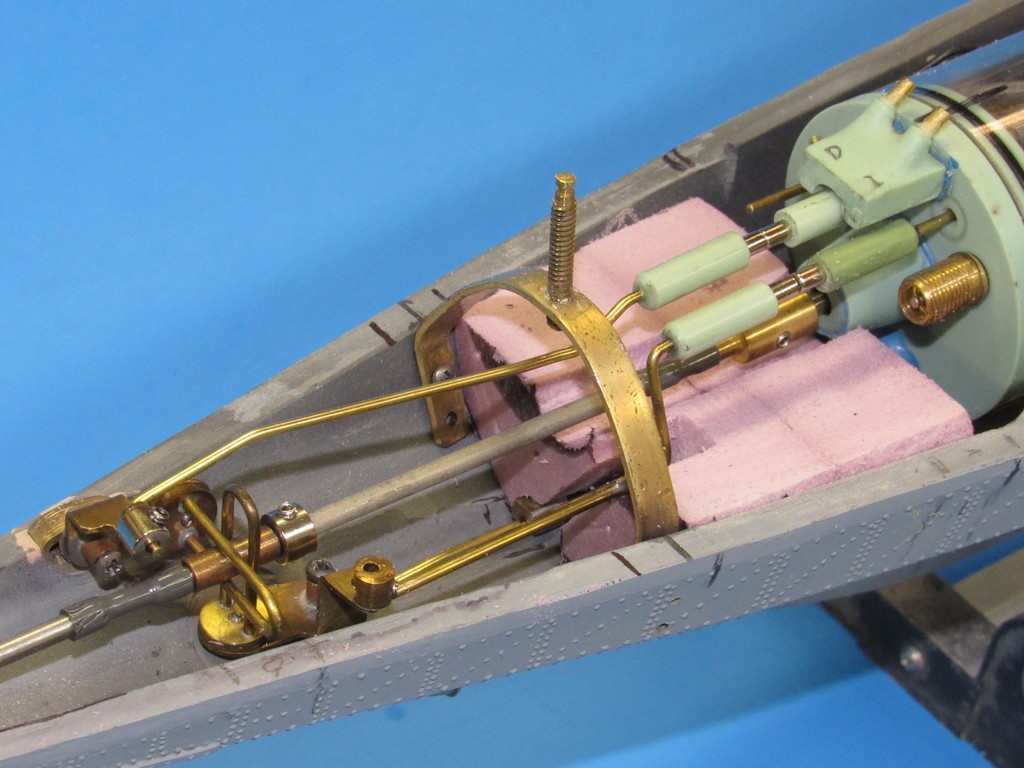

Below is the nose fairing on my Atlantis Sub and the hull of my Pacemaker express sport fisherman (sorry I don't have more pictures of the process)-Best of luck-BG

Leave a comment: