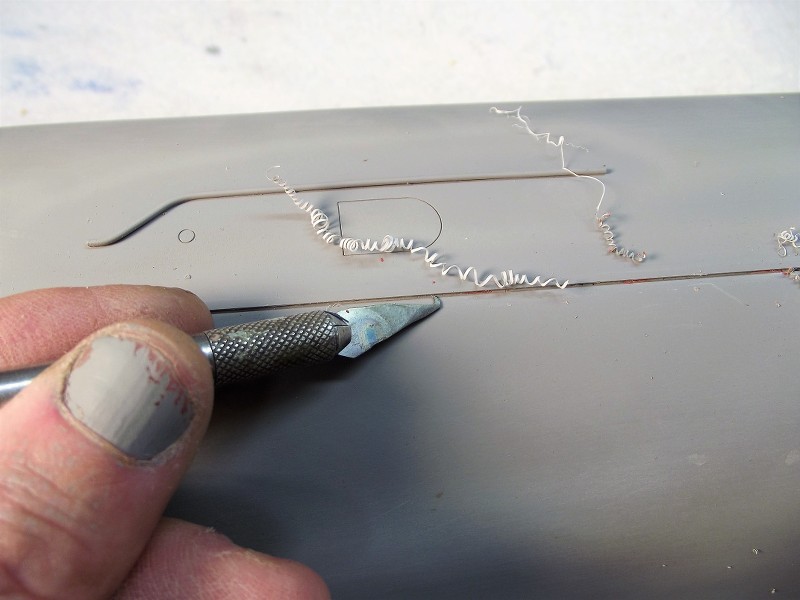

Five to ten firm pulls on this tool and you'll see daylight. Kerf is the width of the tool -- a re-ground #11 used as a blank.

Razor saw?... we need no stink'n razor saw!

(on this job I turned squar-section styrene into T-section to represent external safety-track, but cutting through the hull is another application of this pull-scraper).

David

Leave a comment: