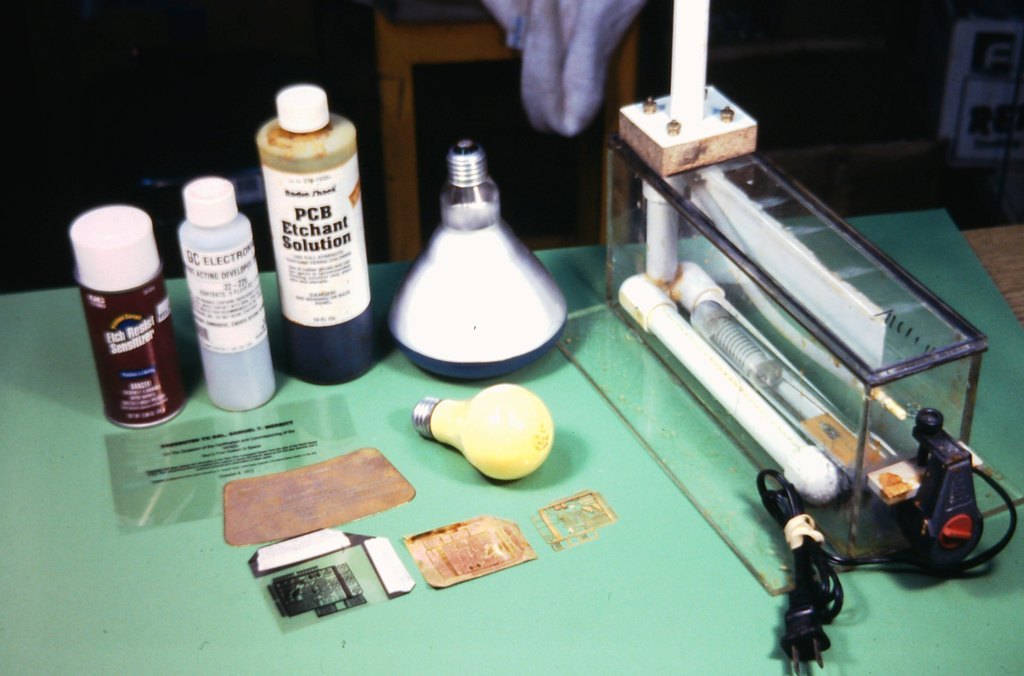

I've never done photo etching. One day I will.

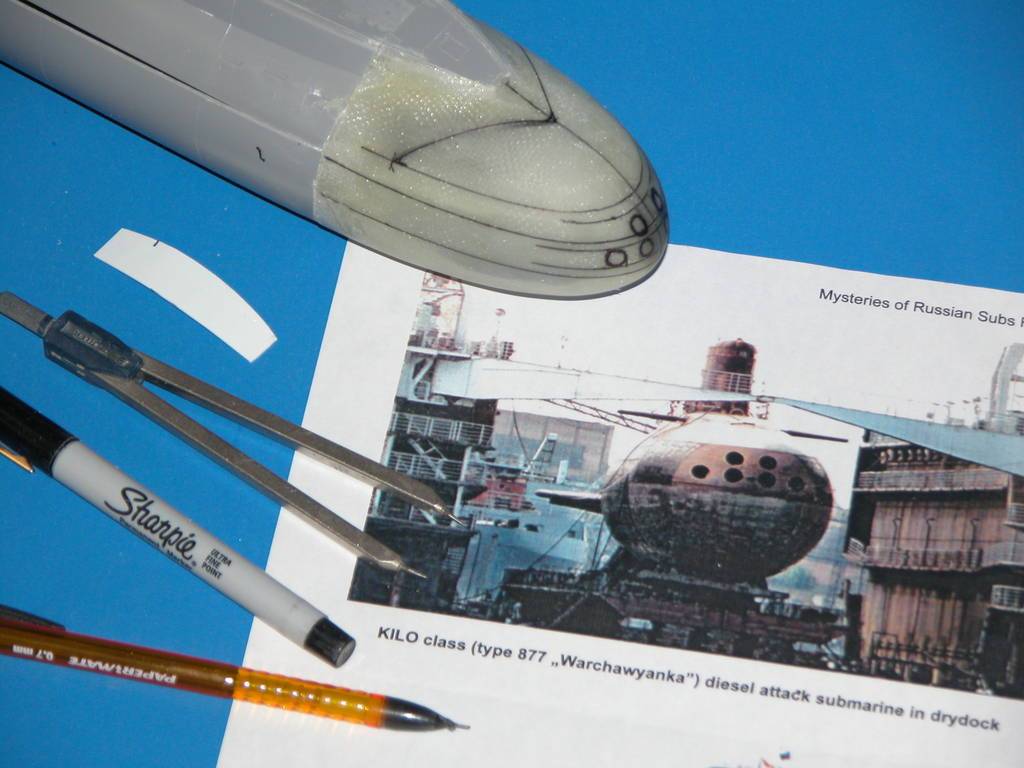

Still going through the slow process of finding the little imperfections in the hull and sanding and filling them out. However in the back of my mind I remembered that I needed to create the last set of pieces for appendages. The rear facing condenser scoops. There are four of these condensers, two on either side of the rear and lower hull. Again, like the forward facing scoops there are few really good close up picks available for me to pull detail from so I have had to get their overall design from a far from a few good but far off photos.

Once again I designed these scoops in Blender. You spend your time producing as accurate as possible one piece. then you just hit shift-D and you have a duplicate, then another and then another..

As far as I can tell there is a grill at the front. I don't know the precise details of it but have recessed the structure only a little. The back end of the scoop reduces and curves down to the center point quite rapidly. After duplicating four I then copied them to a separate file as they were originally build around the overall 667 model. Then send them to the printer. Initially I have found that it is easy to get the scale slightly out with any given print. I started by printing out at least two sets of four each in two slightly different scales in the aim that I'm going to get it right. After about the third go I got it right. I also needed to make sure that they aligned correctly with the model and also the side view drawing that I have been working off.

Of course when the print job is finished, the surface is quite rough and needs a fair amount of sanding. I combine this with spray primer. It requires several layers of primer and sanding. I also combine this with

filler especially in areas where the layering is quite noticeable. Gradually I worked my way down to finer and finer paper. It was a little tricky to spray and work around the grill.

Gradually after lots of layers we get down to 800, then 1200 wet and dry. Then a few coats of primer.

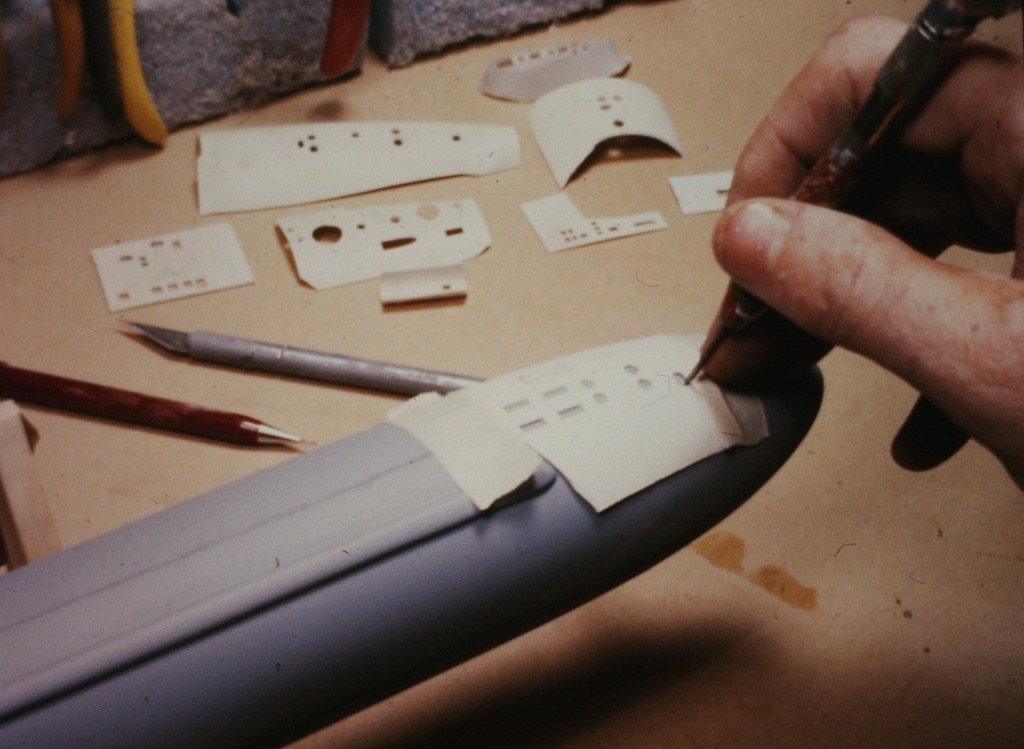

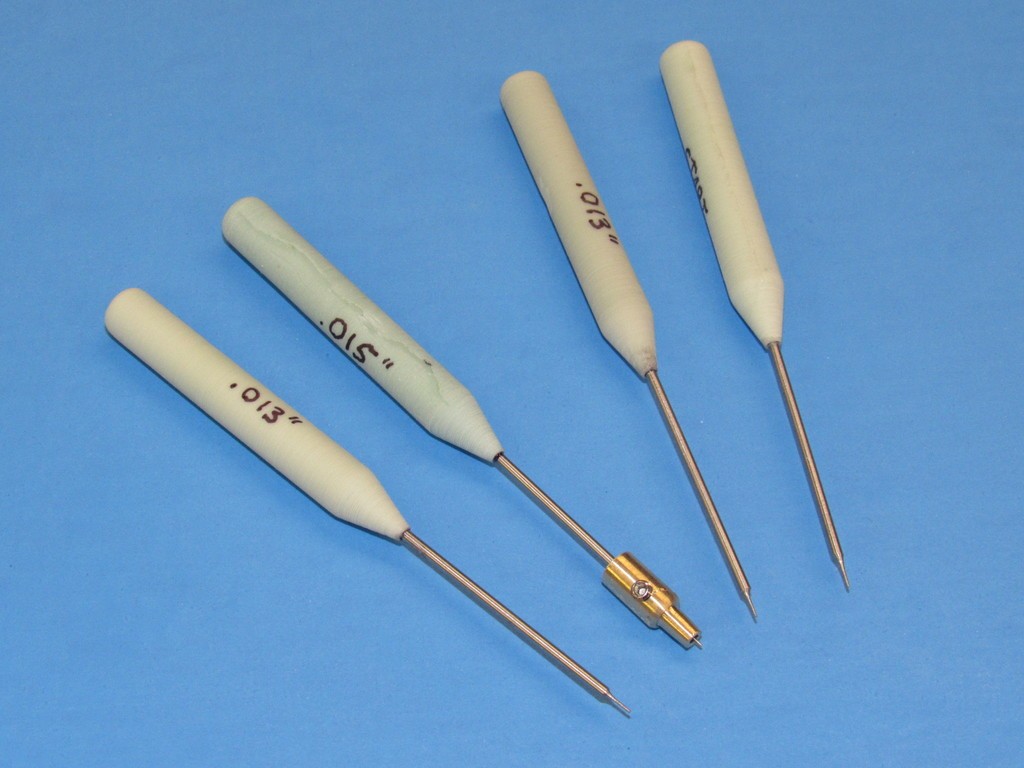

Like the forward facing scoops, I have decided to fix a small round brass piece on the underside of the condensers coops. This is so that you can have the scoop fixed really securely onto the hull. The round brass section simply gives more surface area to affix and helps the parts stay fixed on the model. I took the brass pieces off the masters from the forward facing scoops. This allows consistency across the parts.

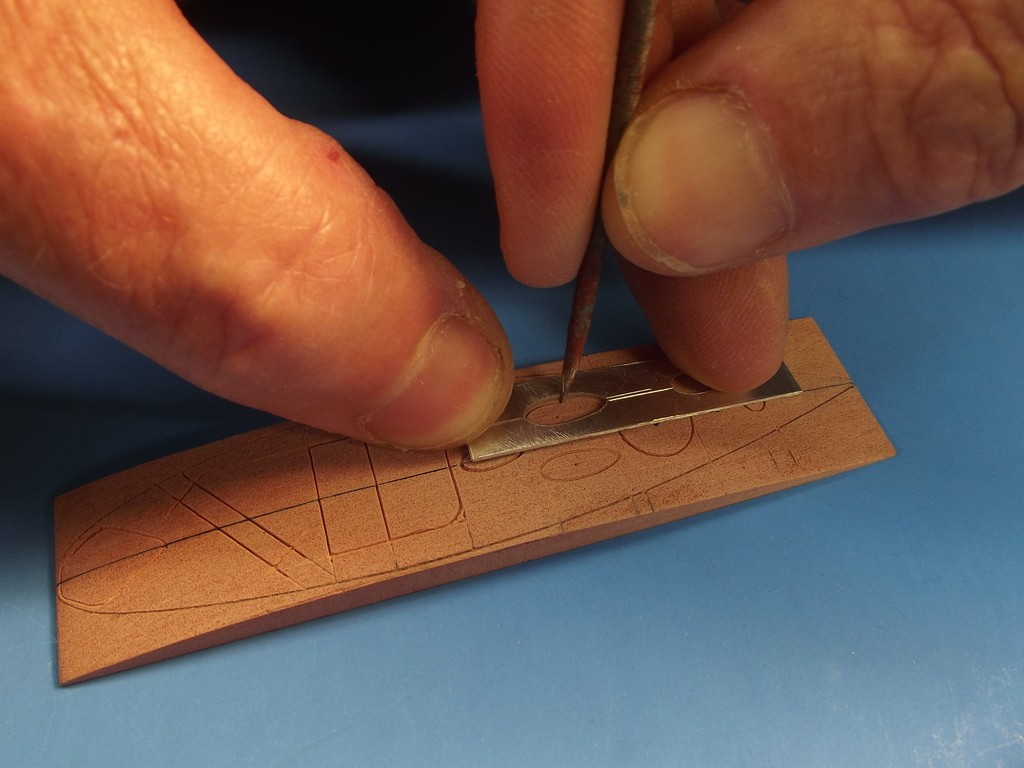

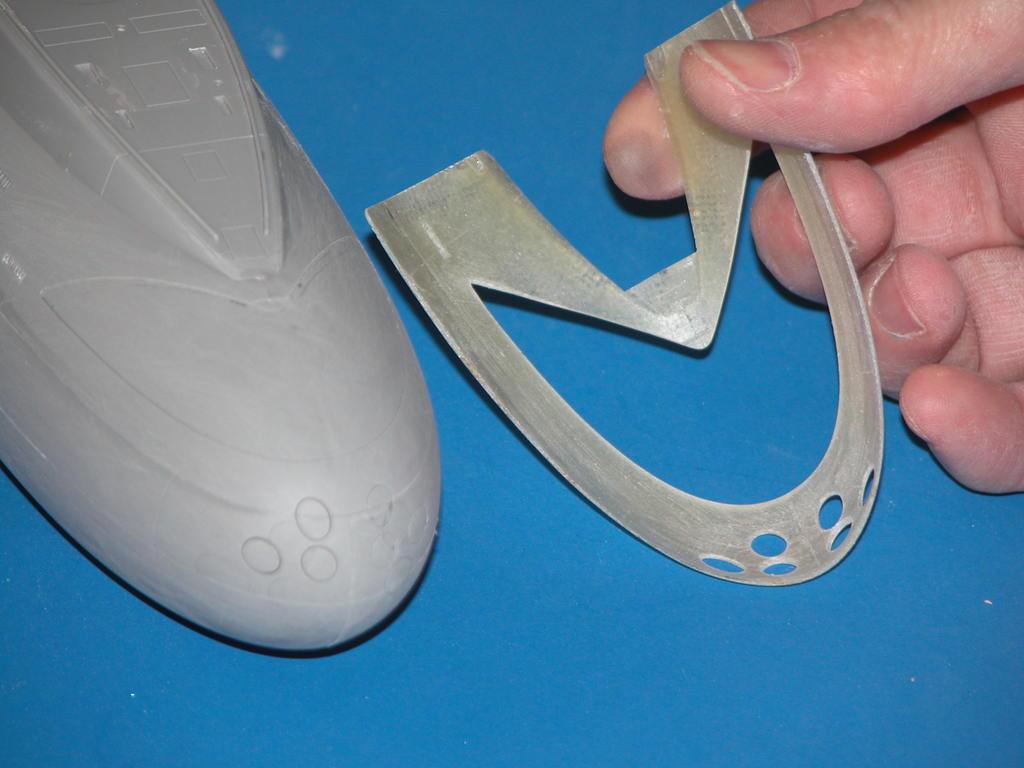

Like the forward scoops, I have used styrene markers to position the scoops on the hull. So I took some 3mm styrene and cut out the profile of the scoop and then cut three more. Then I drilled out the holes that corresponded with the brass pieces that attach to the scoops. These styrene profiles will then be glued to the hull in the relevant locations. This will make it easy for the assembler to get the right spot on the hull.

More later,

David H

Leave a comment: