Scratch Build Soviet Project 667 BDRM Delta IV SSBN K-18 "Karelia" Scale 1/140

Collapse

X

-

-

Mate. A bit harsh. There are VERY few people who can take an idea and make it a reality, no matter how rough around the edges. We are all spoiled rotten by HWSNBN's abilty to produce museum class models with seemingly effortless efficiency. That only takes about 40 years of practice. For the rest of us mortals, results vary with time and experience. DavidH does some fantastic work; I know this because I've seen a lot of it at very close range. His latest challenge is scribing, which will be immencly improved because I know he has just aquired an ENORMUS chunk of Renshape which means that there will be no excuses. Onward Dave!👍 1Comment

-

Oh I was teasing! I don’t honestly think he should do that at all.

Mate. A bit harsh. There are VERY few people who can take an idea and make it a reality, no matter how rough around the edges. We are all spoiled rotten by HWSNBN's abilty to produce museum class models with seemingly effortless efficiency. That only takes about 40 years of practice. For the rest of us mortals, results vary with time and experience. DavidH does some fantastic work; I know this because I've seen a lot of it at very close range. His latest challenge is scribing, which will be immencly improved because I know he has just aquired an ENORMUS chunk of Renshape which means that there will be no excuses. Onward Dave!

I hope David would know that based on the long correspondence we’ve had about this project thus far. All of you - every last one of you are a HELL of a lot more talented than I am. What is incredible is how much we can stand to learn from each other in a venue like this.

For what it’s worth, I still want to buy one of these things when they are ready. I did two weeks ago. I did yesterday when I wrote that. I still do today.Dead men tell no tales...Comment

-

When all the banter is done, I am curious to see how the bondo and masking worked out-I have found that for compound curves, Glad wrap (clear plastic food wrap) and on flat areas-parchment baking paper(my favorite) works well..I hope the tape separates as you expect (if I have to use tape, I wipe it with VERY LITTLE silicon grease on my fingertip)Comment

-

Adding to what Bob said, David - would it be possible to very lightly score along the edge of the tape before you peel it back? That way you can at least encourage which way the cured Bondo will break when you pull it up.Dead men tell no tales...Comment

-

Hello all, wow this thread has been busier than Parramatta road on Friday afternoon.

Darn you HWSNBN!

I’ve spent last weekend re-scribing. I really don’t know if the results have improved the situation. However it has caused the traffic going past this thread to pick up.

In all fairness I did most of the scribing before you gave the detailed run down on tools and scribing technique (which I do appreciate) This is particularly so on the missile deck that was scribed months ago.

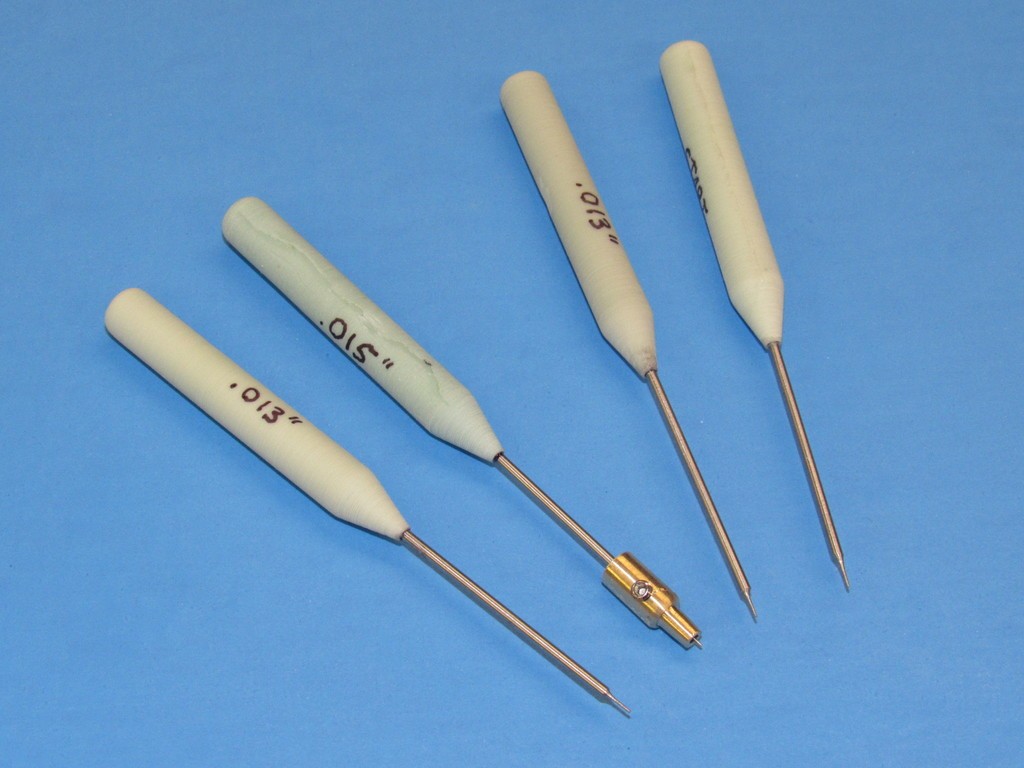

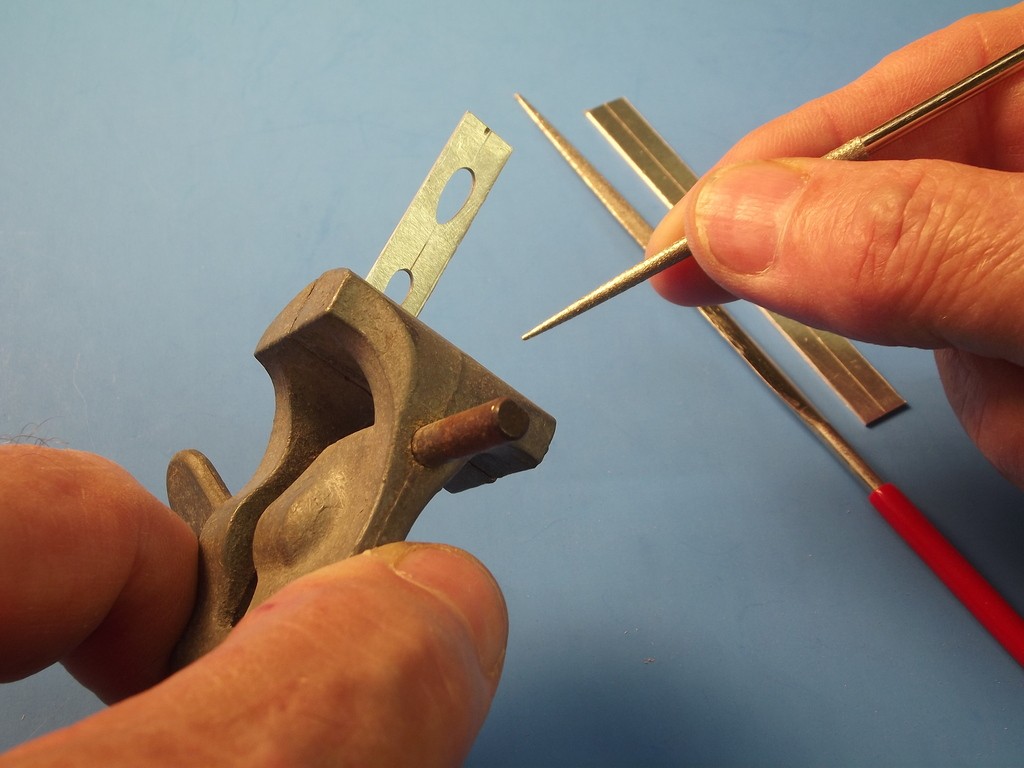

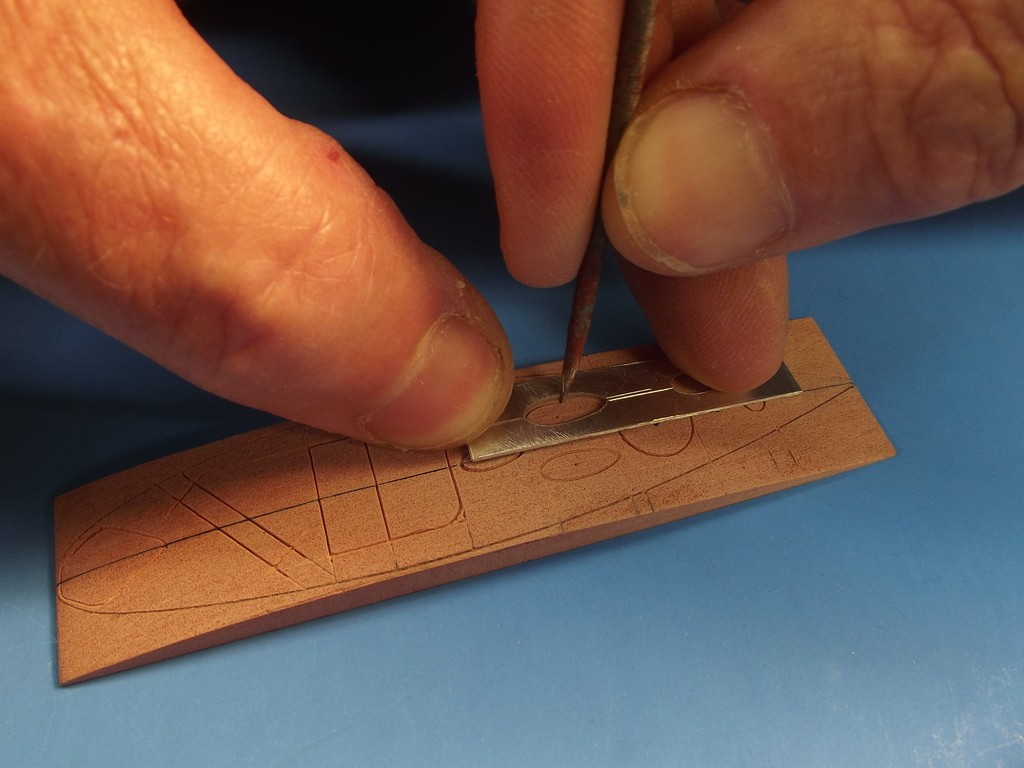

Also almost all the material I am scribing into is Renshape. Yes I am sold on the material. I have ground down some files to really fine points in order to get a really tight and narrow scribe line.

Anyway I sanded back the missile deck and then pasted over filler into the gaps where the scribing was. I have mainly concentrated on the missile deck as this is where I believe most people’s eyes will firstly look at the detail on the hull. Then I came back and sanded down the filler to get it smooth and flat. I then took out my scribing templates and went over the lines of filler in the grooves where the original scribe lines were laid down.

After a while I found that the filler would often pull up in front of the scribing tool as I worked my way along the groove. Obviously it had no bonded with the material inside the groove. This is something that I have had to carefully work around. It has been frustrating to say the least. To try and manage this I have also gone over the grooves with several scribing lines, starting off lightly at first and gradually working my way slowly deeper and hopefully not antagonizing the filler to lift up. A dragging motion is used. The re-scribed lines look more subdued but I don’t know about consistency. I will be going over it again soon. Jury is still out. I also need to sand around the safety railing.

Anyway, back to what I was talking about earlier with creating a tight interface between the top of the missile deck and the rear of the fin. After sanding around the filler that was pressed into the gap between the sail and deck I then pulled the rubber bands off that I had used to secure down the sail and then very carefully wiggled the sail sideways back and forth until the seal had been broken between the filler and the masking tape. This is quite easy to do, as I pulled away the sail there were little thin bits of filler left formed a flange going out radially from the sides. These were quite easy to sand off. I then checked the thickness of the filler from underneath the sail. In some places it was a bit thin so I simply added some super glue to shore it up. Once the super glue had dried it meant that you could sand around these edges with less chance of the filler breaking off. At the same time being careful to maintain the precise profile of the edge that so snugly mates against the hull.

Anyway, thanks for the contribution everyone. Bob, the joint between the sail and the missile deck, I think has worked out well. AS mentioned earlier I have a couple of weeks of fine tuning ahead of me before the hull gets tooled up and also the sail. I also have to do the rear condenser outlets (I think that's what they are?)

Enough for now,

David HComment

-

I am so pleased to see you working the scribing problem, David.

Scribing Bondo is difficult, as you observed. But infinitely easier than scribing wood!

And when you start scribing your next project -- with a proper substrate (gel-coat or RenShape), employing refined engraving tools, and handling those tools with the experience you have gained these last few months -- you'll be amazed at the qualitative difference between it and previous engraving work.

I assure you, sir, once you realize how much you've improved in this area, then you'll appreciate the beatings I've been giving you about the head and shoulders over the matter.

Onward!

David

The HorribleWho is John Galt?Comment

-

-

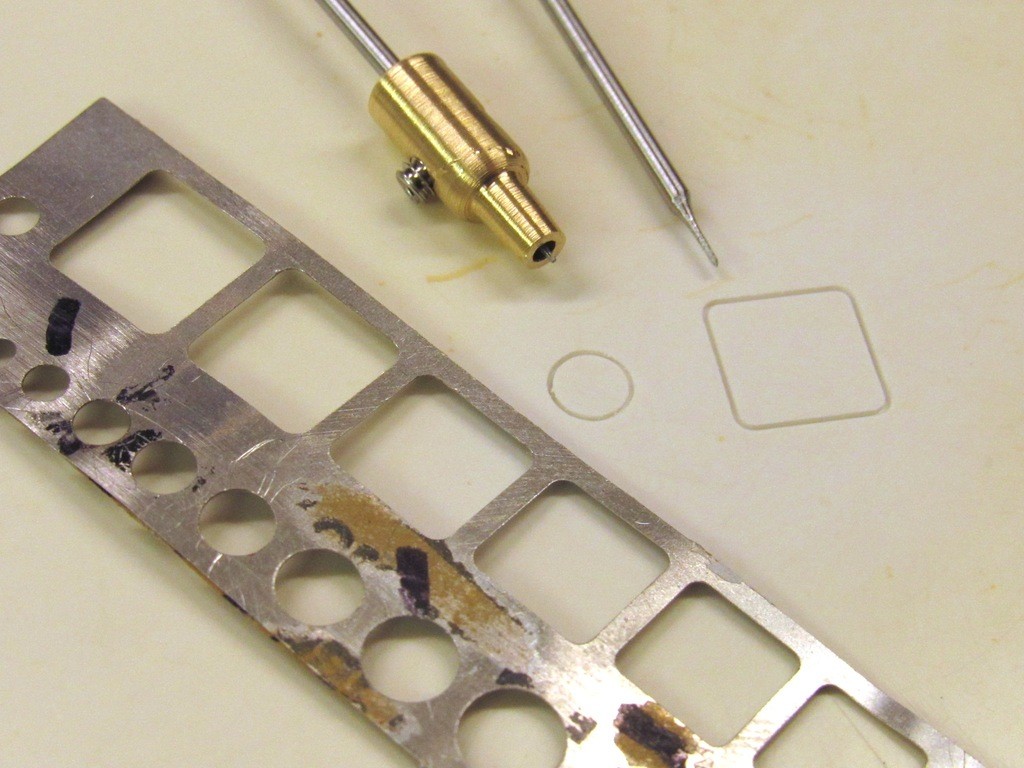

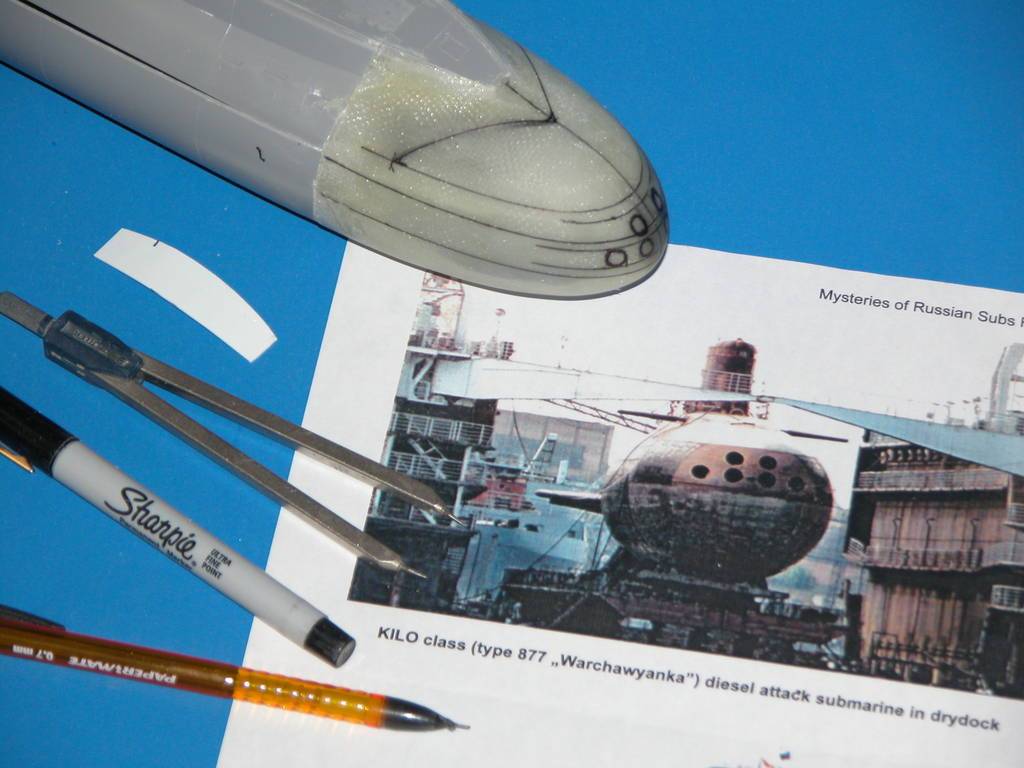

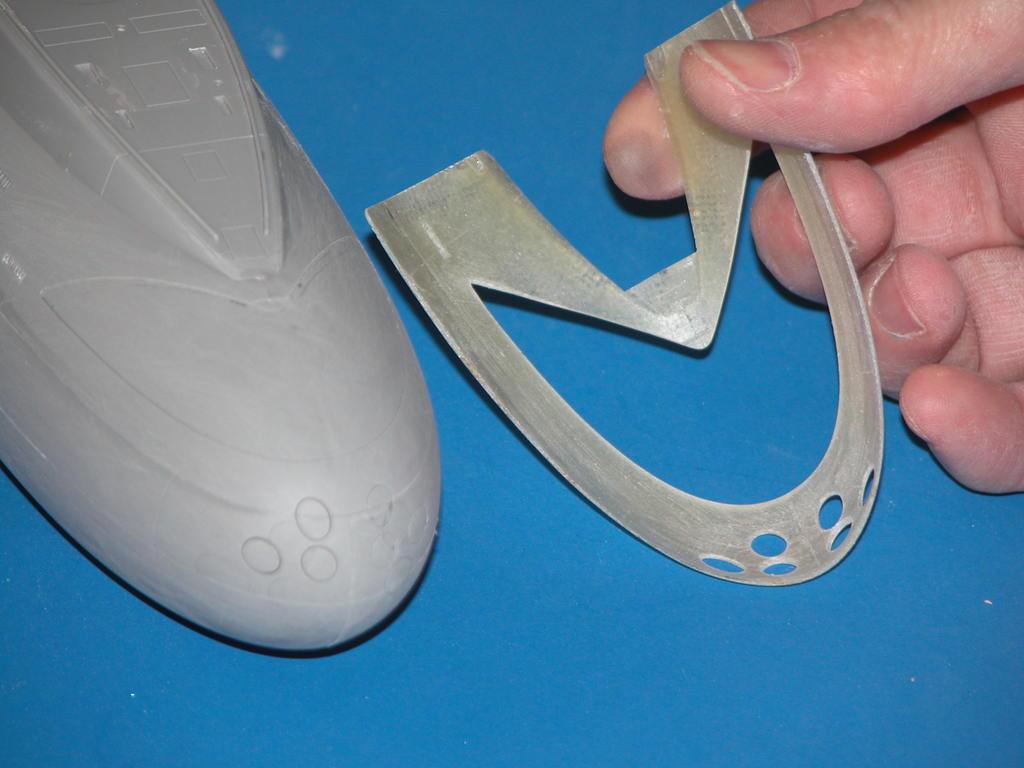

My collection of scribing stencils is a mix of those commercially available, and formed by me. My custom stencils are either punched, drilled, milled, and filed to shape from plastic sheet, G-15, aluminum or brass sheet; my own acid-etching process is employed to produce some types of engraving stencils; or uniquely vacuformed or GRP laid-up stencils formed over the area to be engraved.

Use of the commercial stencils -- some specifically sold for engraving, others, simple plastic drafting forms -- is fine for the standard geometric shapes like squares, circles, straight lines, and the like. But You have to make your own stencil for shapes unique to the subject getting engraved.

The more exotic scribing stencils are the vacuformed or GRP laid-up ones used to engrave missile hatches, torpedo tube shutter doors and sonar dome windows.

DavidWho is John Galt?👍 1Comment

-

Comment

Comment