First off...

Merry Christmas ya'all!!

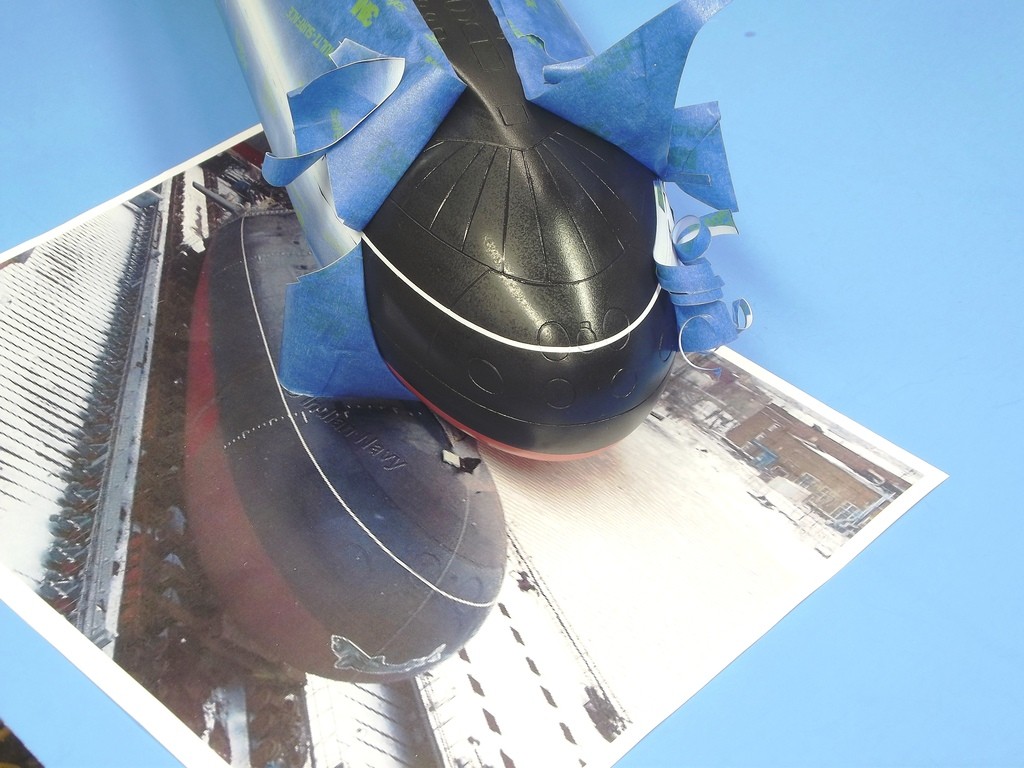

Regarding the email "subject", it's been many years since I touched traditional styrene model kits. So in effect, that part of building is quite rusty. My RC boat's are built more for functionality than display, so I don't mind sand scrapes, bent scopes and "whiskey "dings. IOW, detailing is not primary, it's actually 3rd after Survivability and Functionality. They're models I play with, static models are where I like to stretch my detailing craftsmanship. I'm not saying I haven't seen "museum" or 'mantle" quality hit the water and run as flawless as they look, I just don't personally count myself among that elite group.

Now loookit what the Krampus dropped off !! (For some strange reason, it brings me the gifts.)

Anyway, I'm beginning to amass quite a static collection as you can see for my future Sci-Fi "Air,Space and Sea" collection that will be displayed in the Recreation/Shop room.

Two more kits are pending to complete the collection. PAN AM ORION also from 2001, which not only complement the new Discovery XD-1, but the 707 you see there which will display PAN AM colors instead of AF1 (the $5 open box flea market buy had no decals), showing a timeline promised but never happening. Also in the buy que is a 1/144 Scale Saturn V scale matching Discovery. Our greatest achievement, yet greatest dropped ball at the same time.

Anyway...don't get me started as to what happened politically.

Dave, specifically for you when you get a free moment, hopefully before 2023.

Having been out of the styrene world for many years, what do you recommend for best results?

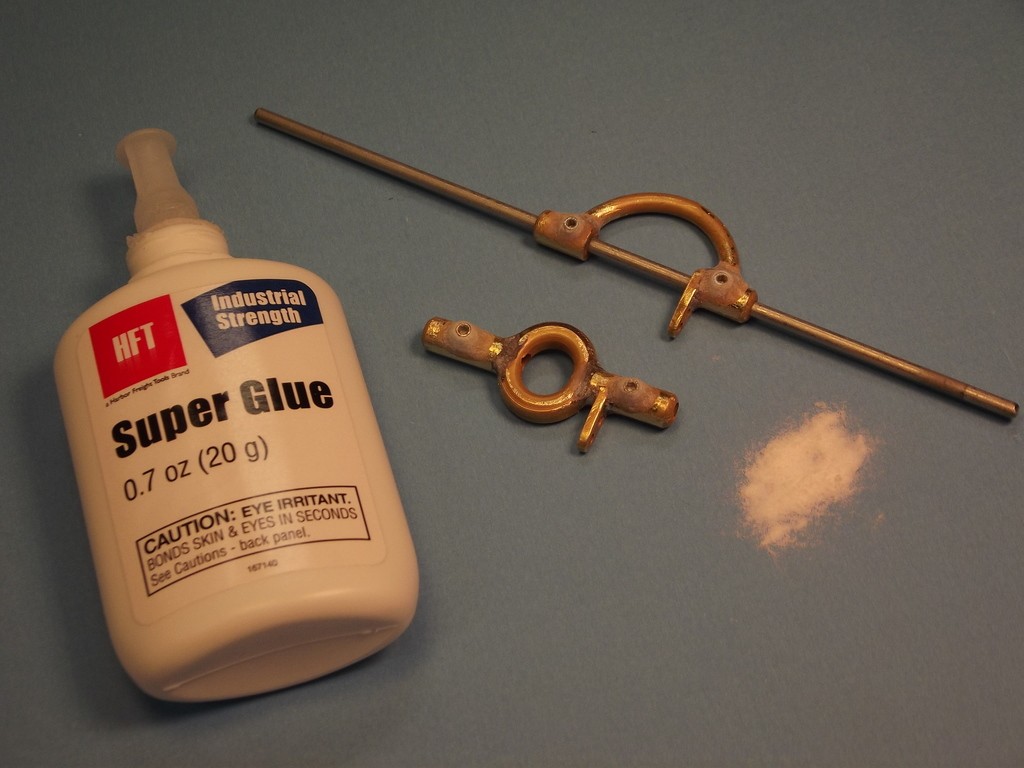

Adhesives (People still use Testor's Cement?)

Fillers for joints (I loathed the white Testor's stuff)

Paint, Primer (I used Tamiya Acrylics in the past, which I loved)

Tools (Decent Airbrush etc)

Reference Material (You tube authors you like etc)

Any model with an interior will (J2, PROTEUS,VOYAGER, SPINDRIFT etc....) will be built without them as they will be suspended "in flight" from the ceiling. The interiors to be used for future shelf mount dioramas. So I plan to light these (aren't modern, lower power LED's wonderful!) and I'm concerned with light bleed through the plastic, so any tips to handle that is welcome. J2 rotating Fusion core itself makes it worth it!!

Any help would be appreciated because I'm sure this particular hobby has come a long way since I l was last prolific with it in the late '80's.

Thanks in advance

"Sub" Ed

PS If someone know where I can get a model of the "Dove" (From Doppleganger, aka Journey to the Far Side of the Sun) that would really crown the collection!

Merry Christmas ya'all!!

Regarding the email "subject", it's been many years since I touched traditional styrene model kits. So in effect, that part of building is quite rusty. My RC boat's are built more for functionality than display, so I don't mind sand scrapes, bent scopes and "whiskey "dings. IOW, detailing is not primary, it's actually 3rd after Survivability and Functionality. They're models I play with, static models are where I like to stretch my detailing craftsmanship. I'm not saying I haven't seen "museum" or 'mantle" quality hit the water and run as flawless as they look, I just don't personally count myself among that elite group.

Now loookit what the Krampus dropped off !! (For some strange reason, it brings me the gifts.)

Anyway, I'm beginning to amass quite a static collection as you can see for my future Sci-Fi "Air,Space and Sea" collection that will be displayed in the Recreation/Shop room.

Two more kits are pending to complete the collection. PAN AM ORION also from 2001, which not only complement the new Discovery XD-1, but the 707 you see there which will display PAN AM colors instead of AF1 (the $5 open box flea market buy had no decals), showing a timeline promised but never happening. Also in the buy que is a 1/144 Scale Saturn V scale matching Discovery. Our greatest achievement, yet greatest dropped ball at the same time.

Anyway...don't get me started as to what happened politically.

Dave, specifically for you when you get a free moment, hopefully before 2023.

Having been out of the styrene world for many years, what do you recommend for best results?

Adhesives (People still use Testor's Cement?)

Fillers for joints (I loathed the white Testor's stuff)

Paint, Primer (I used Tamiya Acrylics in the past, which I loved)

Tools (Decent Airbrush etc)

Reference Material (You tube authors you like etc)

Any model with an interior will (J2, PROTEUS,VOYAGER, SPINDRIFT etc....) will be built without them as they will be suspended "in flight" from the ceiling. The interiors to be used for future shelf mount dioramas. So I plan to light these (aren't modern, lower power LED's wonderful!) and I'm concerned with light bleed through the plastic, so any tips to handle that is welcome. J2 rotating Fusion core itself makes it worth it!!

Any help would be appreciated because I'm sure this particular hobby has come a long way since I l was last prolific with it in the late '80's.

Thanks in advance

"Sub" Ed

PS If someone know where I can get a model of the "Dove" (From Doppleganger, aka Journey to the Far Side of the Sun) that would really crown the collection!

Comment