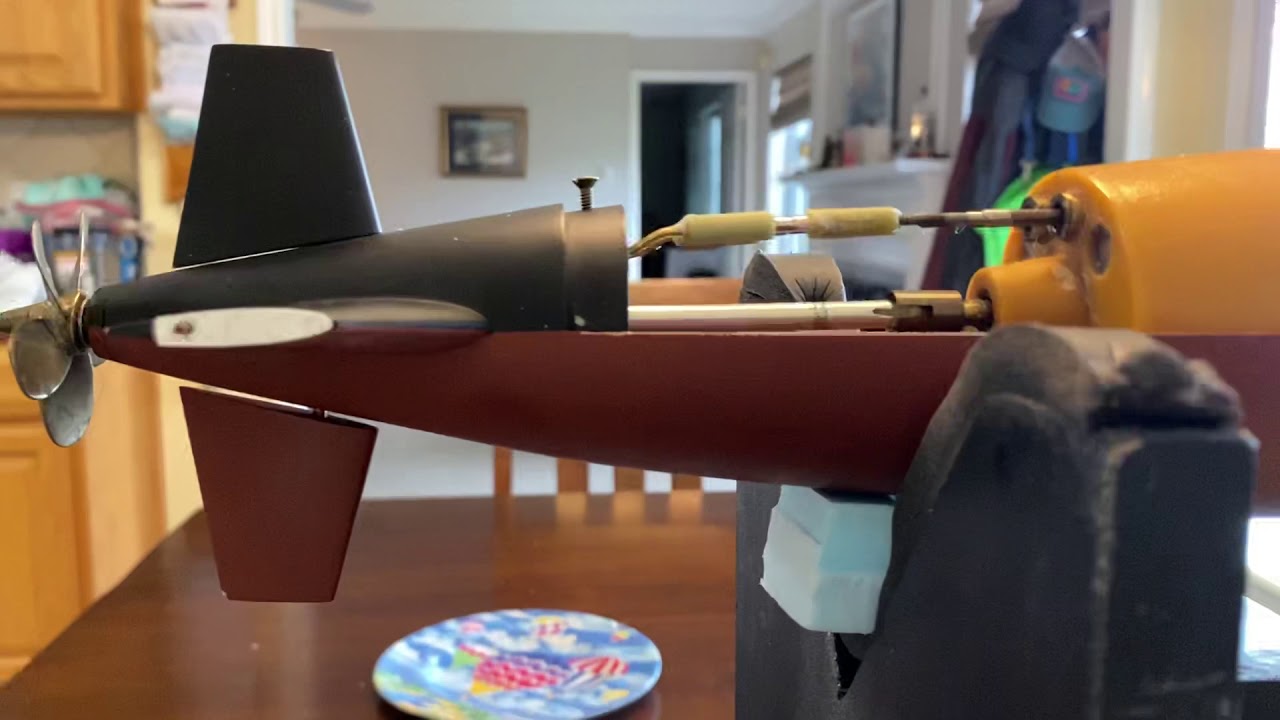

Ok I got the AD2 auto level installed and set up. It wasn’t that hard after re reading the directions. Now I have a pitch plane servo throw issue. The servo has a much larger throw forward toward the bow (up planes) than rear ward (down planes). So with the WTC in the hull and the links connected and the pitch planes neutral I get decent down plane travel but for up planes it pulls the magnetic couplers apart at max up travel. I don’t have much adjustment left in the screwed on coupler or inside the WTC at the servo. Why does the servo rotate farther one way than the other? I have tried changing the rod connection hole on the servo arm and even rotating the servo on the gear with no real difference.

Any suggestions? I thought servos should have equal travel in either direction.

Any suggestions? I thought servos should have equal travel in either direction.

Comment