Hello all, I have a 3.5 inch SAS sub driver that I've been working on and I finally got the electronics done and moved onto hardware. I rigged it up and ran into some problems when working on the sub driver. First I have no clue how to rig up the safety valve. Currently it's attached from one end to the induction line. I assume that's wrong since I've seen the cross section if the thing and am guessing it doesn't work right if it's not even connected. Oops. Secondly I've noticed the line running from the output of the pump that blows air into the tank floods when the water inside the ballast tank reaches it! Now I've bought a one way air valve but I've never seen anyone else use one, so how do you guys prevent this problem? Another problem I've noticed is fluttering of channels. I read the adf2 spikes power and this can be fixed with a glitch buster. So I bought one. It's shipping but I still wonder if there are any other things that can cause this. I'll let you all know if any other problems arise and I would appreciate all the help I can get, I'm fairly new to this hobby Thanks!

SAS cylinder build up questions

Collapse

X

-

Tags: None

-

First, welcome! the 3.5" Sub-Driver is very nice size and gives you room to work in. Pictures help. I am not clear on the first question. Pictures help - especially me, I like photos or crayon drawings or any visual aids.

Water getting to the pump is not a problem as long as it does not leak into the cylinder. However, you say the tank floods when the water inside ballast tank reaches it. Please elaborate. Do you mean once it is put in the water the tank fills with water and does not hold the air in the tank? Do you see where the air is escaping from? In other words it is not coming from the vent? You should not need a one way valve and at the moment I would not add one. Let us find the issue.

Did you test the pump to make sure which side is in and which side is out? Please verify this and again pictures help.

Fluttering of channels can be caused by a myriad of reasons. Glitch buster can help, ferrite rings can help, but it can also be caused by an ESC, motors that do not have capacitors on them, bad joints, receiver or transmitter interference, and other areas.

Hope this helps and please let us know if anything has helped.

Peace,

Tom

If you can cut, drill, saw, hit things and swear a lot, you're well on the way to building a working model sub. -

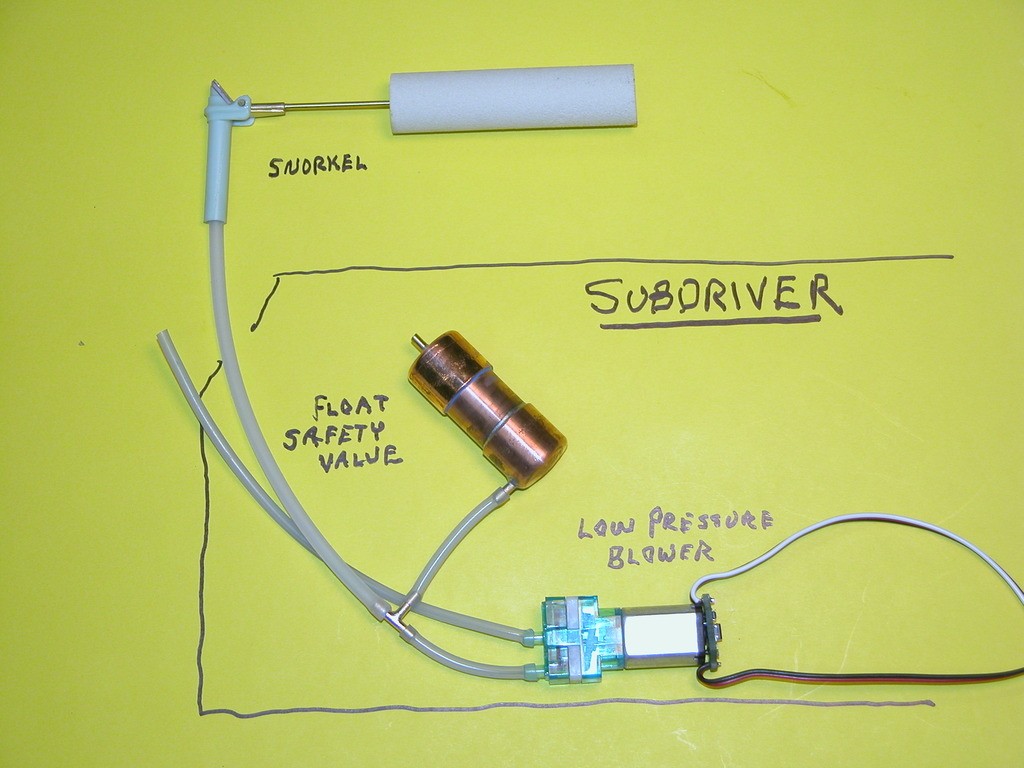

I am not home to check but I think the safety valve might be hooked up correctly. It is a check valve to keep water from coming into the cylinder from the snorkel re-pressurizing the cylinder.

Tom is right, the air pump itself should not allow water to get into the cylinder.

For the glitching, make sure the motors have capacitors on them, disconnect the linkage to the servos and check one servo at a time to help narrow down the cause.Comment

-

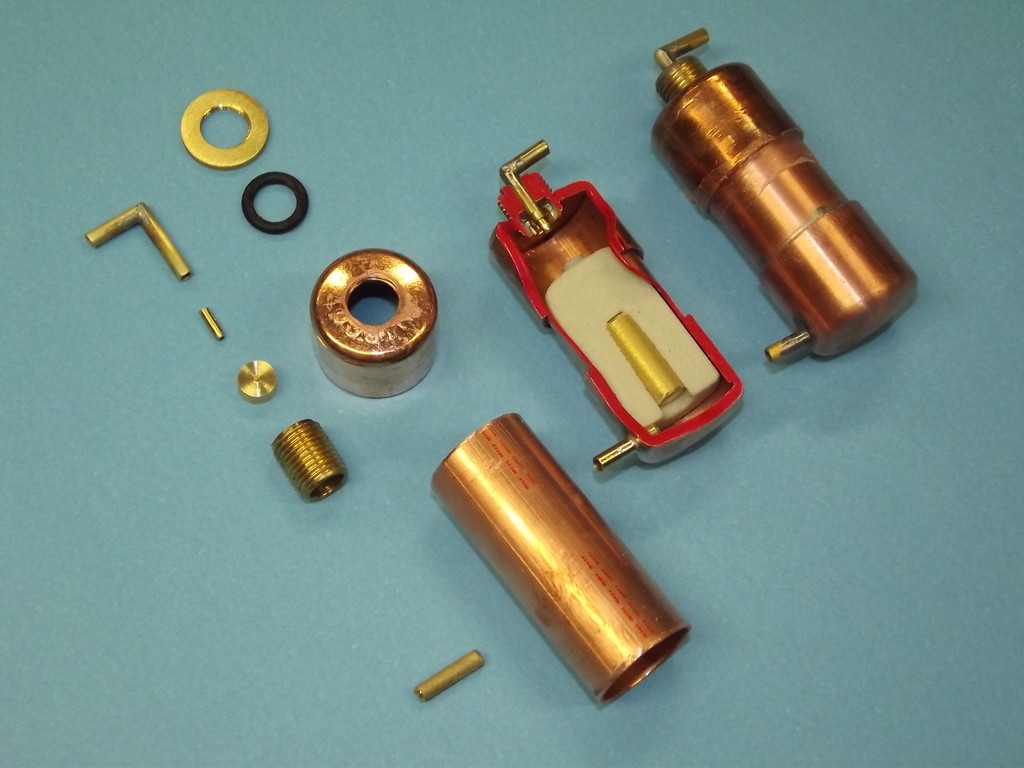

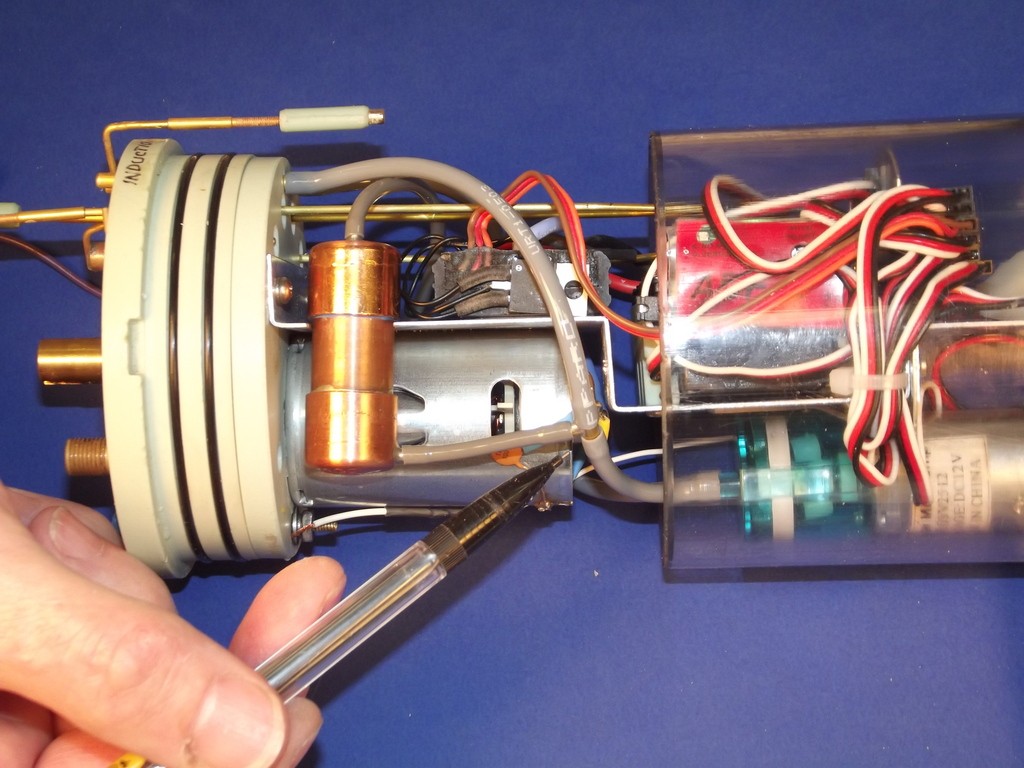

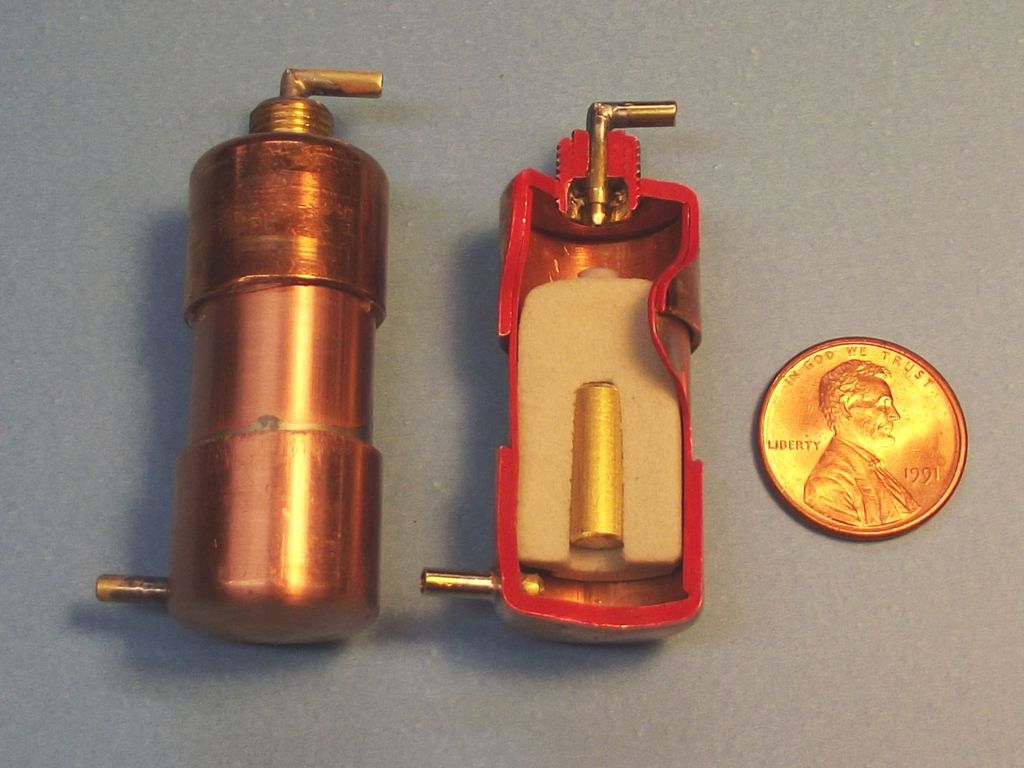

I have included some photos here, I do not have any capacitors on the motor to my knowledge, any advice what to get and what to do with it? Thank you so much guys!3 PhotosYa know, I quite like sinking skimmers!Comment

-

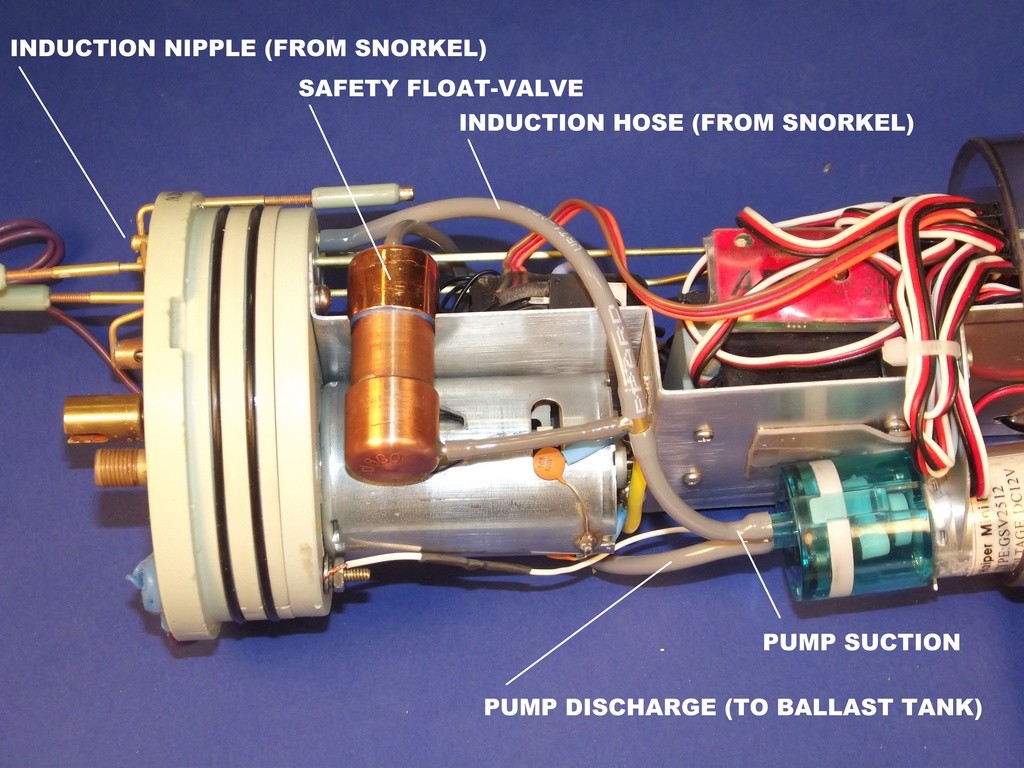

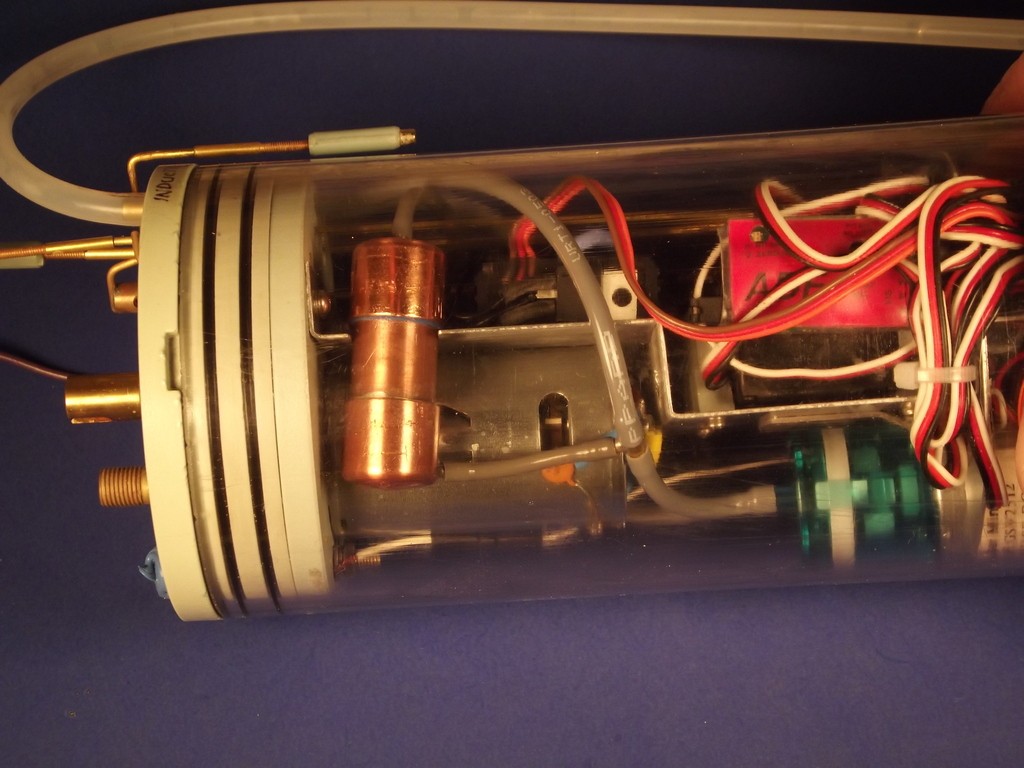

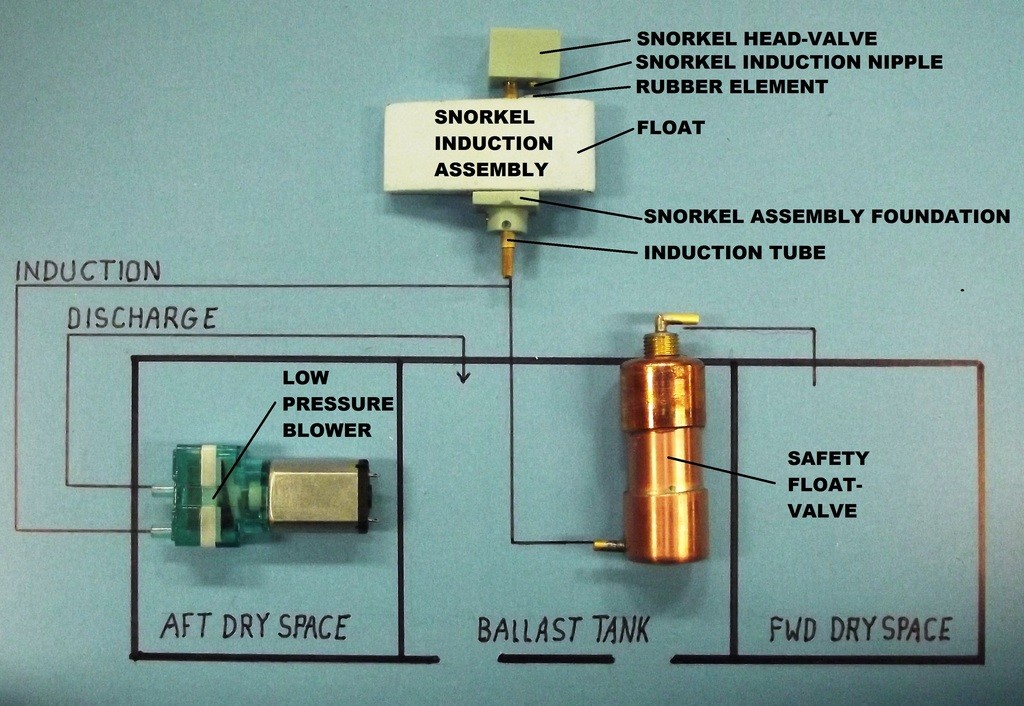

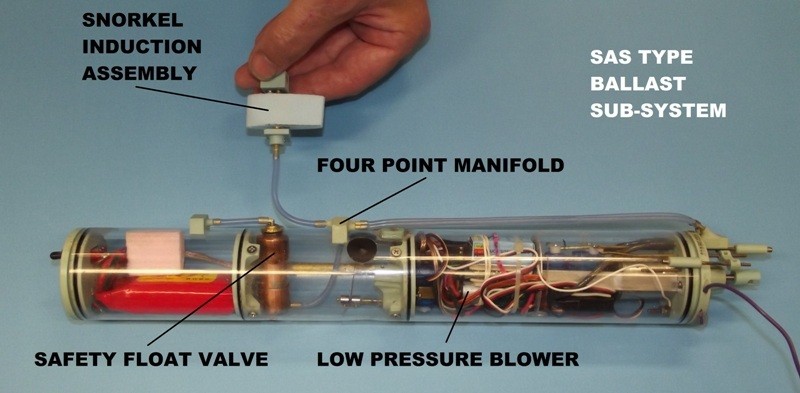

That 555 motor has internal spark-suppression capacitors installed. Looking at the backside of the motor bulkhead, forward: the starboard nipple makes up to the snorkel induction (through the pass-through pipe, starboard side on the four-point manifold), the port nipple discharges into the ballast tank through the port side of that manifold.

The internal plumbing arrived to you installed and tested, don't mess with it. That brass item is the float safety-valve. It allows internal air to be sucked by the pump and blown into the ballast tank when the snorkel valve is closed. The internal float will close the valve if water gets past the snorkel and into the induction side of the plumbing, preventing catastrophic flooding.

DavidWho is John Galt?Comment

-

A piece of advice for when you get all this rigged and ready to get wet. Take the closed up SD, flip it upside down and shake the bejeezus out of it a few times until you can hear the float inside the safety float valve body move back and forth. I had mine hang up a bit when I was first trying to figure this out and found that I was still ingesting a bit of water into the dry spaces. You're a lucky man that you don't have to fish it out of the ballast tank if it ever needs servicing.

PS - I like your taste in avatars!Dead men tell no tales...Comment

Comment