Broadly speaking there are two categories of plastics: thermoplastics, and thermosets. The heat stretching process, described here, can only be accomplished on a thermoplastic. In this category are included polystyrene, ABS, acrylic and many other formulations. It’s been my experience that styrene is the best formulation for heat-stretching.

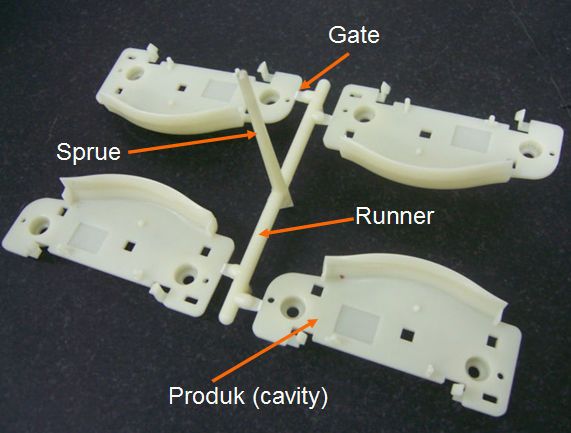

Of interest to us are the plastic discards from plastic model kits, often referred to as the ‘sprue’. This is a misnomer. In fact, what we salvaged from those kits are ‘runners’ – artifacts of the injection forming process (the sprue never makes it into the box, these are snipped off at the point of manufacture and recycled into the production process). These runners are typically cylindrical in cross section and vary in thickness from 1/16” to as large as ¼”.

The process of ‘sprue stretching’ is the reduction of a plastics cross section through drawing. Not through a die, but through the application of heat and carefully applied pulling to not only reduce the cross section, but also -- through timing and selective heat application -- to achieve tapper.

Typical uses of the technique by the model builder/kit-assembler are to achieve antenna-wire, whip antennas, gun barrels, stanchions, cable-runs, conduit, ect.

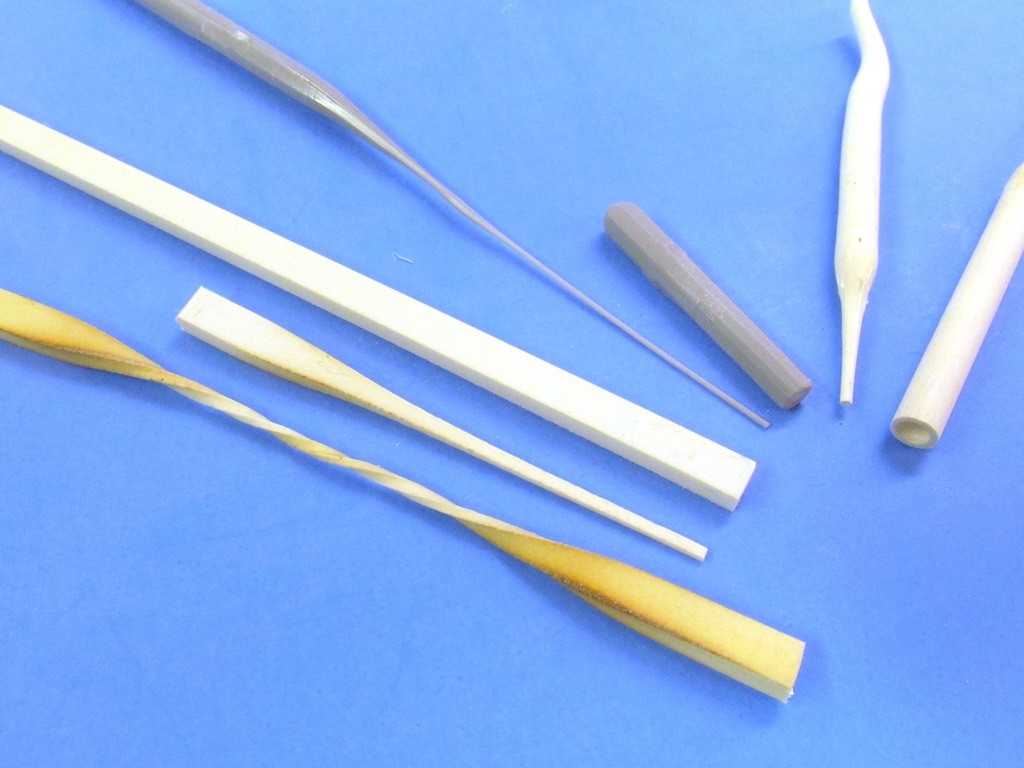

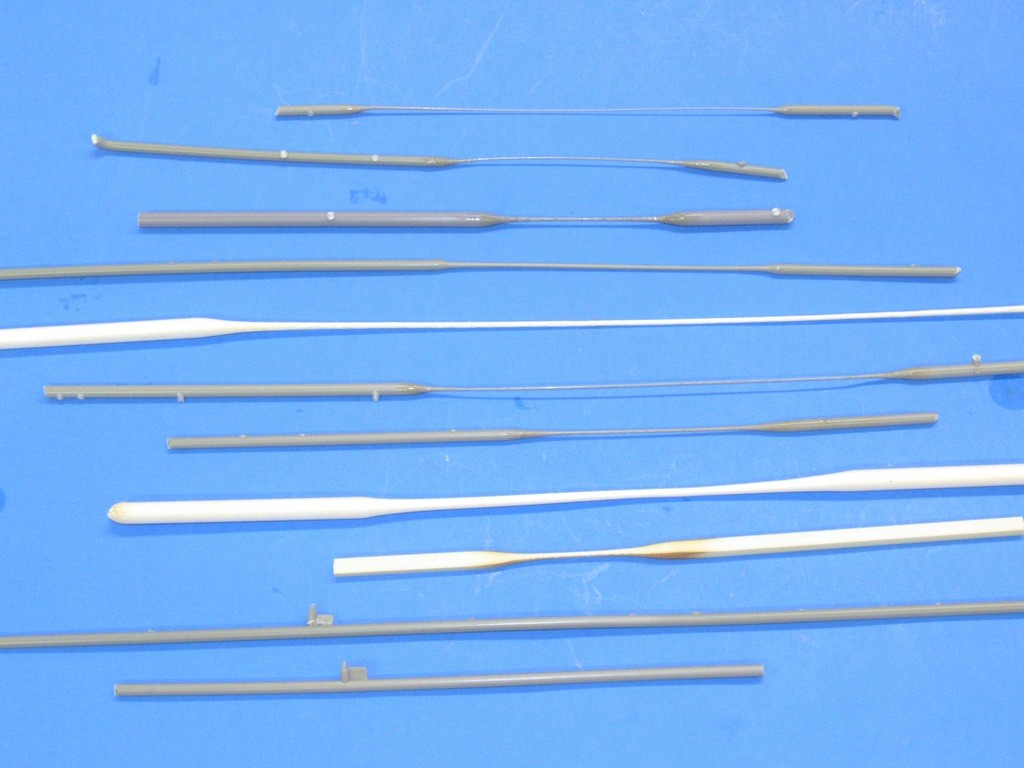

All of the gray pieces pictured are kit provided polystyrene runners. The white stuff is pre-formed shapes manufactured from ABS plastic. Note how I’ve been able to achieve varied cross section diameters and degree of tapper. An acquired skill, I can assure you.

The two bottom pieces are lengths of runners freshly liberated from a plastic model airplane kit. Note the still attached ‘gates’.

Over the decades I have gathered a considerable collection of thermoplastic extrusions, as this photo demonstrates.

You have a length of H-beam too large of section for your model? Just heat it up, pull it to size, and you’re good to go!

The neat thing about sprue stretching is that no matter the cross-section shape of the item at the beginning, the resulting reduced-in-size- cross-section of the stretched item is proportionately identical to the shape you started with.

You don’t have to be a slave to the cross section of plastic you have on hand. You can pre-form the cross section – as I’m doing here on this length of runner – and then heat-stretch it to the desired diameter. In this case I require itsy-bitsy little hex section length, which will become bolt-heads. I start with a comfortably sized piece of runner, perform a little shaving action with the X-Acto blade on it, and I’m ready to heat the work and draw it to the required diameter. Nothing to it!

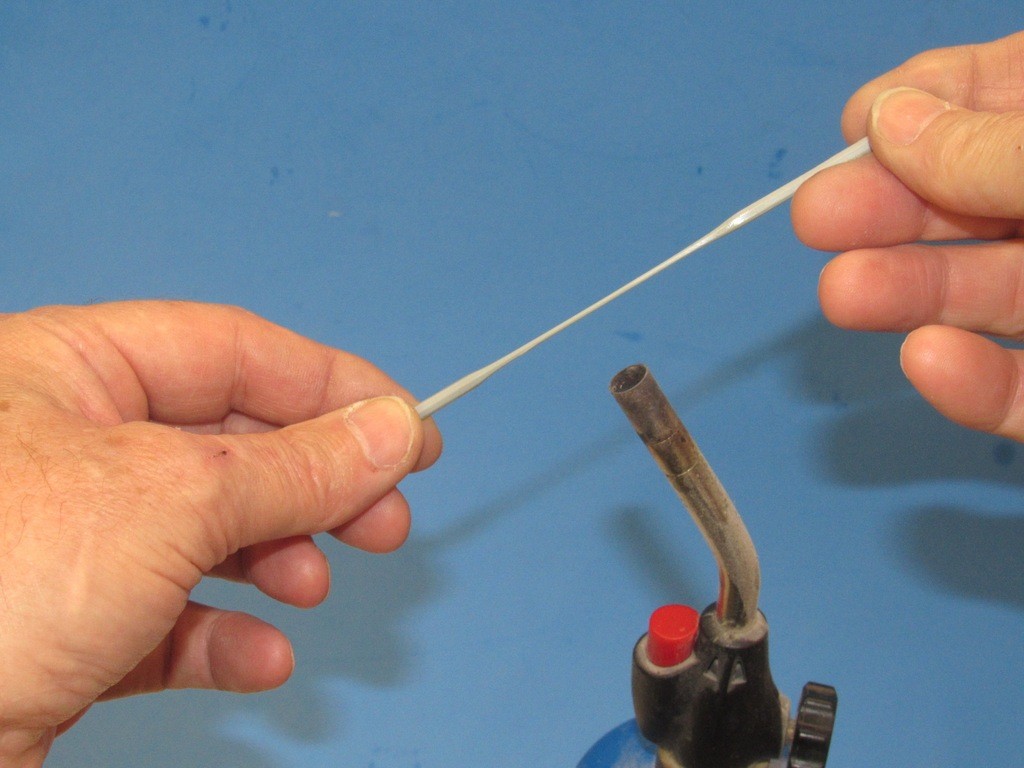

I prefer to employ a torch as a heat source. Some prefer the open flame of a candle. Whatever blows up your skirt. As long as the heat can be applied where you want it and you can control the heat rate by moving of the work in relation to the heat source.

Putting a point on the fact that heat stretching a shape only reduces its diameter, not its shape, is this collection of various shapes (circular, square, tube, and hexagonal) – the original piece next to the stretched item drawn from it.

Sometimes I can’t help being a smart-ass about it: note the ‘twisted’ stretched rectangular sectioned piece of ABS – wrought-iron poker, anyone?

Stretching thermoplastic tubes offers the ability of sleeve lengths of tapered plastic into one another, to achieve such model parts as vertical communications whip-antennas and the like.