Hi all

I was hoping I could get some help from some people with real experience because I am new to this hobby and I have no idea what I am doing.

I want to make a DPV (Diver Propulsion Vehicle) and I came to this site because I figured they are very similar to the kind of RC submarines that are made on this site just a whole lot simpler. I am having trouble figuring out what the best way to stop water from leaking through the drive shaft but everything I have looked at is either to expensive or wont work. I say too expensive because have a huge budget and the whole idea is to make something that is cheaper to build then to buy a ready made vehicle from a manufacturer.

I am running a 14.4 volt motor I salvaged from an old battery drill (that still works :D) that runs at 1400rpm. This will be powered by the same battery that the drill runs off and will be controlled by a simple momentary action switch mounted to the outside of the WTC. The motor and battery will be housed inside a PVC pipe with an end cap at one end that the driveshaft will go through and a watertight threaded cap on the other end so I can access the motor and replace the battery.

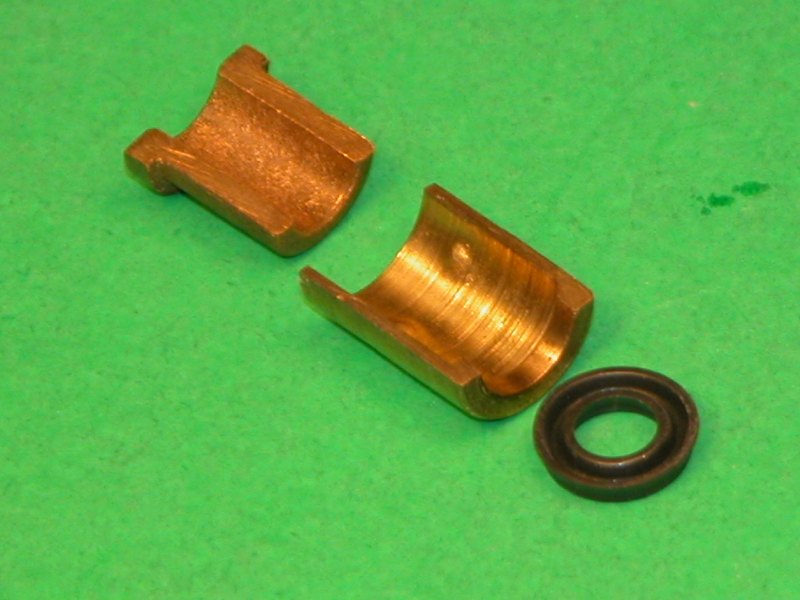

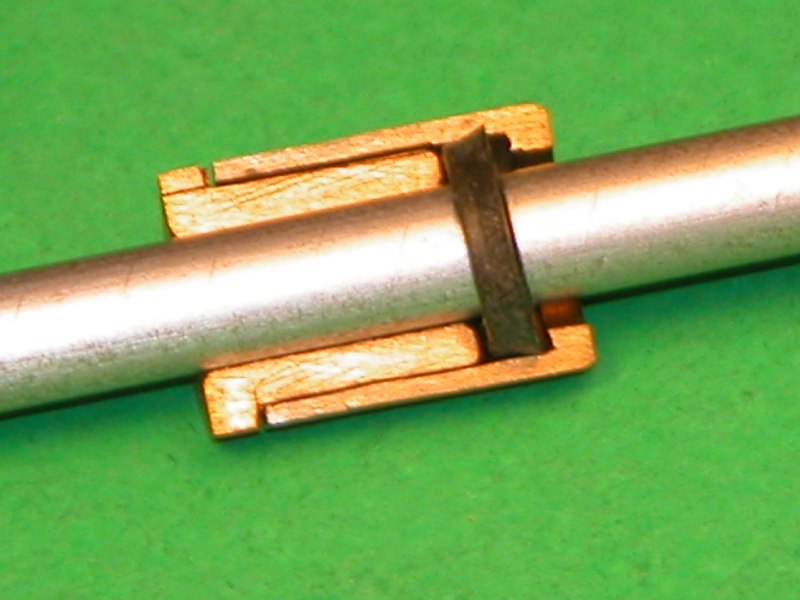

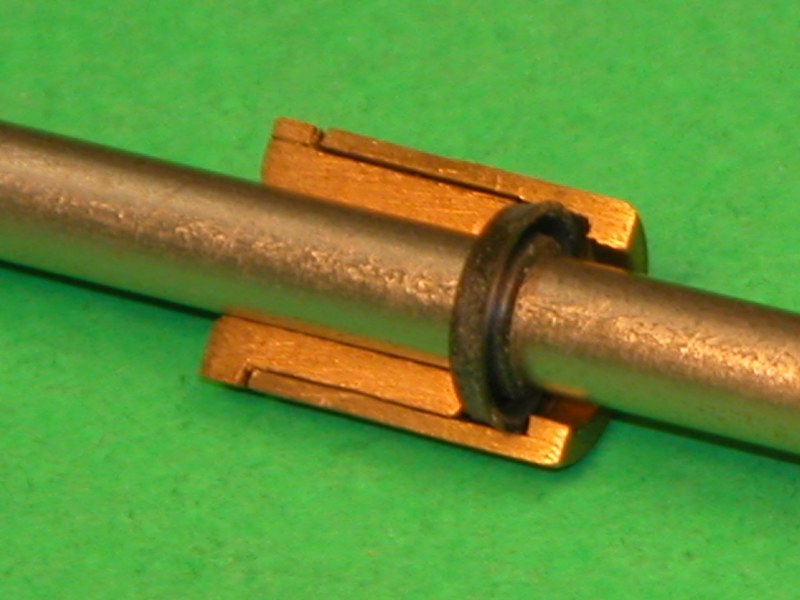

Does anyone have any good ideas for making sure the driveshaft is watertight however? I was thinking of using a stuffing tube but I am worried it will be too weak and will just snap off. I have also considered using a mechanical/shaft seal similar to what they use on larger boats just scaled down so they fit inside water pumps.

Sorry if all this seems like nonsense, I am very new to this but I love to build things. Thank you for taking the time to read my post!

I was hoping I could get some help from some people with real experience because I am new to this hobby and I have no idea what I am doing.

I want to make a DPV (Diver Propulsion Vehicle) and I came to this site because I figured they are very similar to the kind of RC submarines that are made on this site just a whole lot simpler. I am having trouble figuring out what the best way to stop water from leaking through the drive shaft but everything I have looked at is either to expensive or wont work. I say too expensive because have a huge budget and the whole idea is to make something that is cheaper to build then to buy a ready made vehicle from a manufacturer.

I am running a 14.4 volt motor I salvaged from an old battery drill (that still works :D) that runs at 1400rpm. This will be powered by the same battery that the drill runs off and will be controlled by a simple momentary action switch mounted to the outside of the WTC. The motor and battery will be housed inside a PVC pipe with an end cap at one end that the driveshaft will go through and a watertight threaded cap on the other end so I can access the motor and replace the battery.

Does anyone have any good ideas for making sure the driveshaft is watertight however? I was thinking of using a stuffing tube but I am worried it will be too weak and will just snap off. I have also considered using a mechanical/shaft seal similar to what they use on larger boats just scaled down so they fit inside water pumps.

Sorry if all this seems like nonsense, I am very new to this but I love to build things. Thank you for taking the time to read my post!

Comment