I had to replace the ballast servo so I had to pull the bulkhead out to do so. Everything is back together, but in doing adjustments, I'm not sure where the failsafe blow valve should be positioned. With the left stick full left it opens the ballast valve. With the left stick full right the valve is closed and the pump operates. So how do I position the valve. I never did have this working from day one.

WTC Maintenance, need help

Collapse

X

-

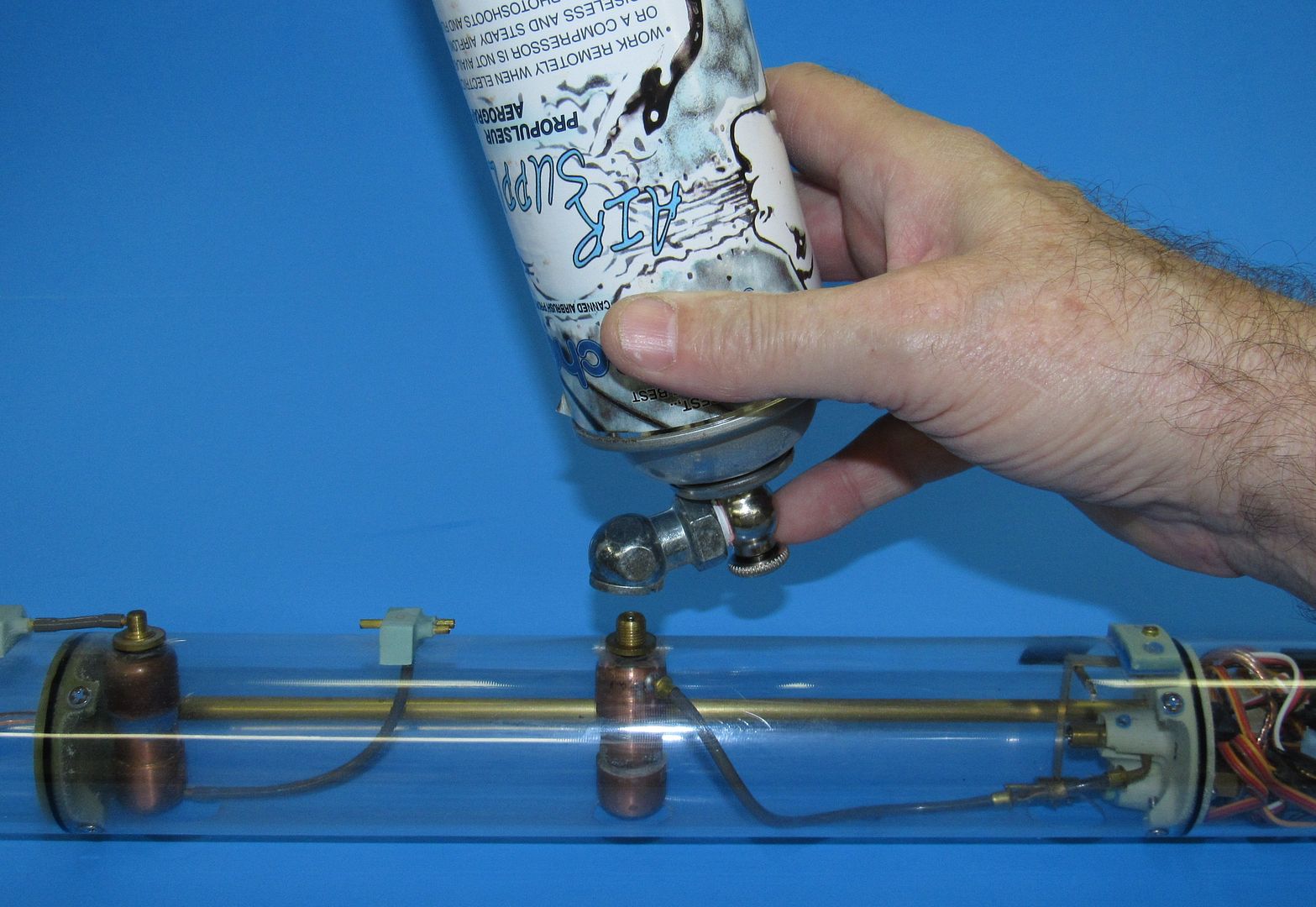

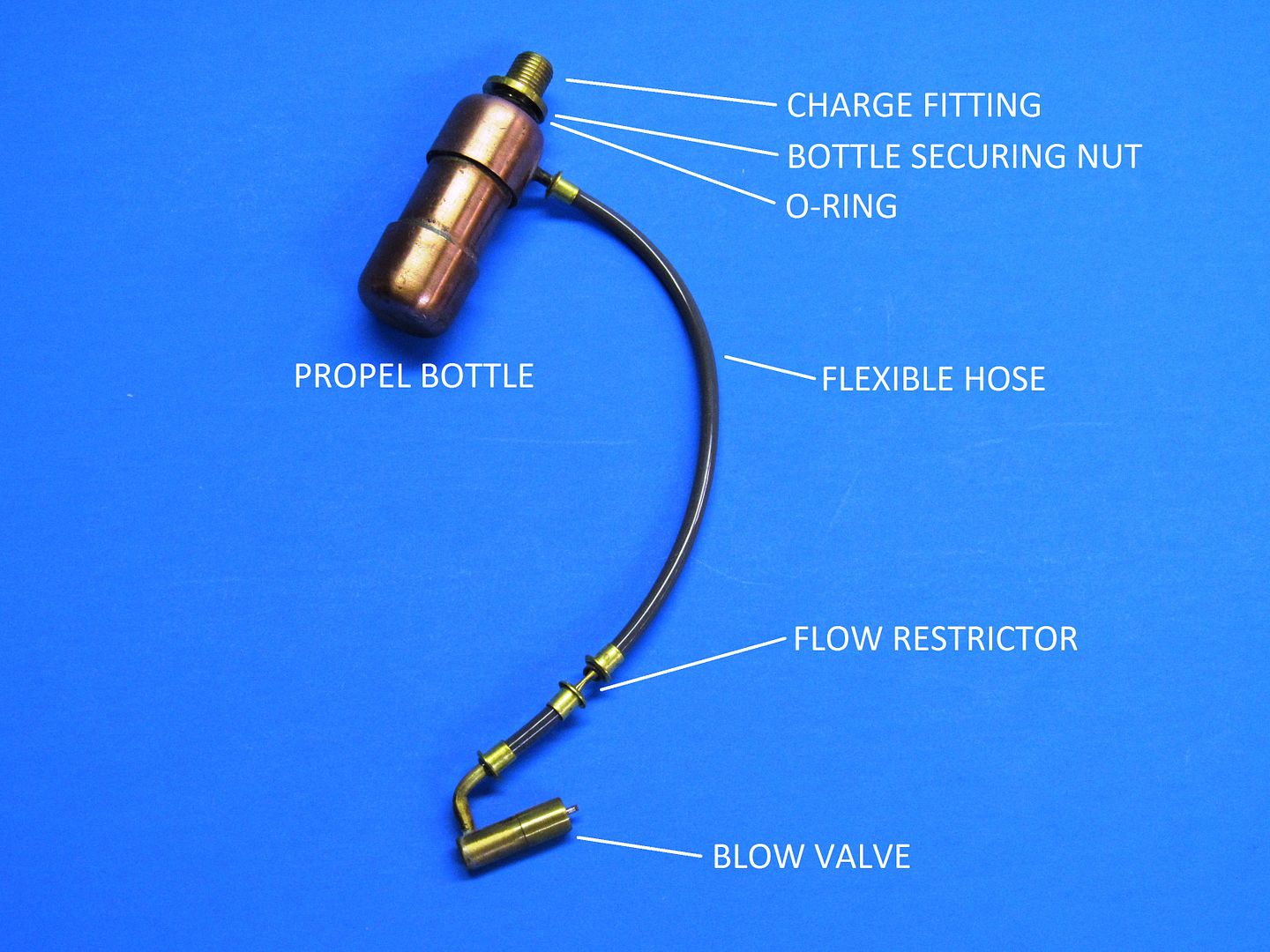

GAS BALLAST BLOW AS SECONDARY MEANS OF BALLAST WATER DISCHARGE If the objective is to use the GBB as a secondary means of expelling ballast water, you have to rig things so that no gas is released during normal (transmitter directed) operation of the SAS ballast sub-system. In this mode you only want a gas ‘blow’ during the fail-safe command issued shortly after loss-of-signal.

This is achieved by the ballast sub-system linkage moving a short distance, not enough to engage the blow valve actuating stem, during normal blow; and a greater distance, enough to engage the valve stem of the blow valve actuating stem, during fail-safe operation.

Most fail-safe devices permit you to set the degree of servo motion when the device goes to the loss-of-signal, ‘blow’ mode. And you either program that loss-of-signal servo position into the fail-safe device directly through analog potentiometer, or a ‘set’-button during the fail-safe device set-up routine

How? ...

… ...You read the frig’n instructions that came with the fail-safe device! That’s how.

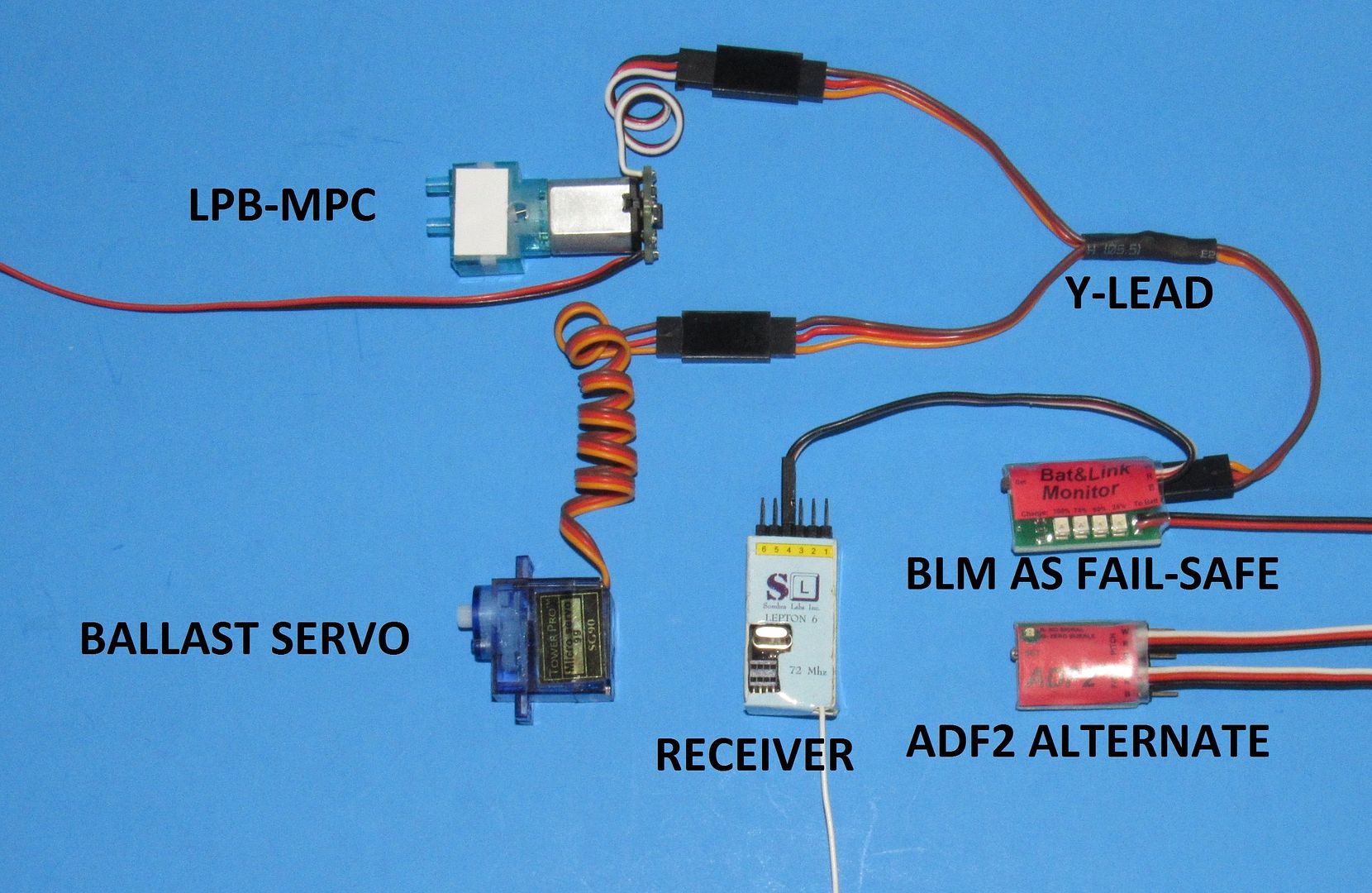

The above bread-board device layout represents a SAS type primary ballast sub-system. The only engagement the GBB has is through the linkage operated by the ballast servo, that linkage engaging the gas ballast device blow valve when the servo is over-positioned by the fail-safe device upon loss-of-signal. Normal transmitted commands do not over-position the servo, so no discharge of gas occurs during the ‘blow’ command.

Your fail-safe device instructions will tell you how to set for maximum servo throw when loss-of-signal occurs.

At the transmitter set the end-point of the 'blow' direction to minimum, just enough to turn on the LPB, but not enough to pull the ballasts linkage-arm back enough to actuate the GBB blow valve.

DavidLast edited by He Who Shall Not Be Named; 02-21-2017, 08:55 PM.Who is John Galt?

Comment