Until now I was NOT reading your postings.....but now that I did the answer is probably the same....I hate both of you.

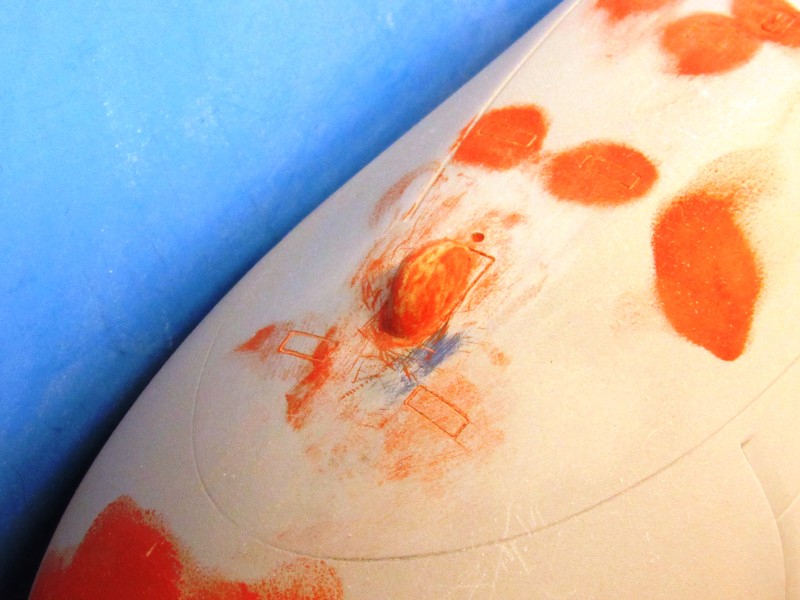

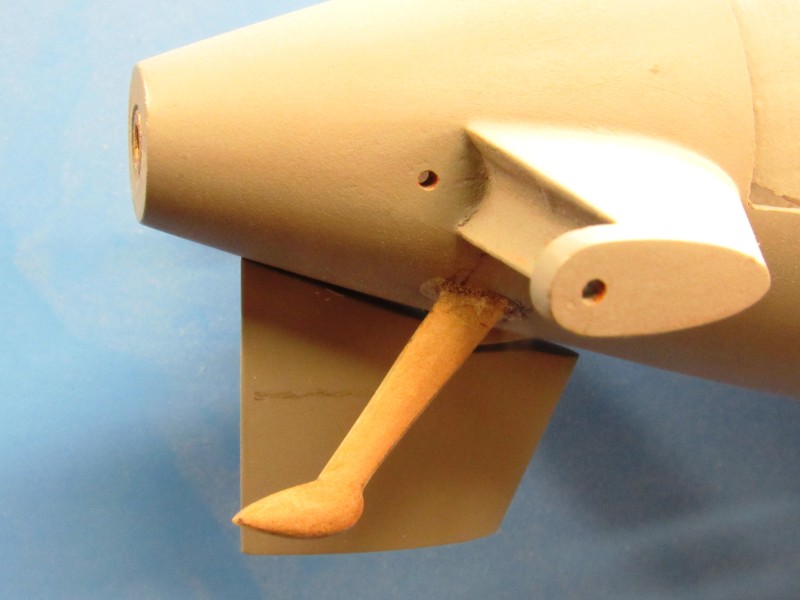

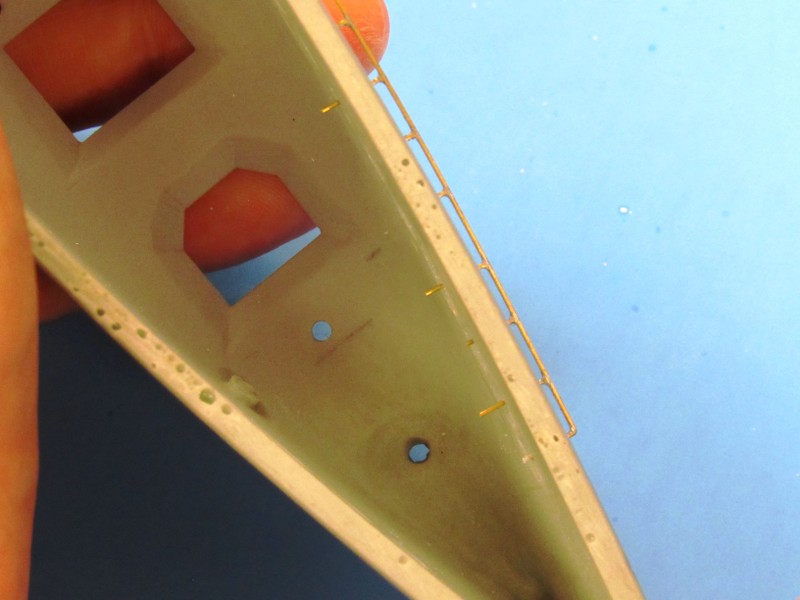

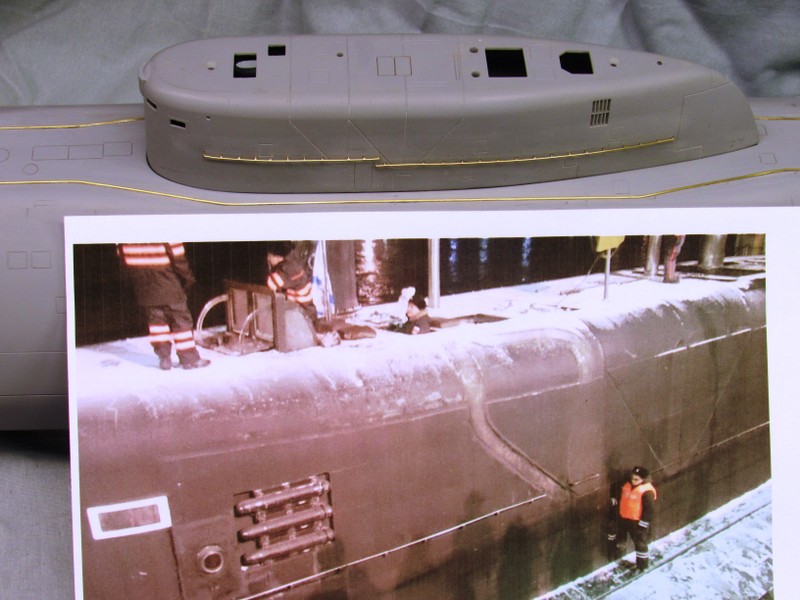

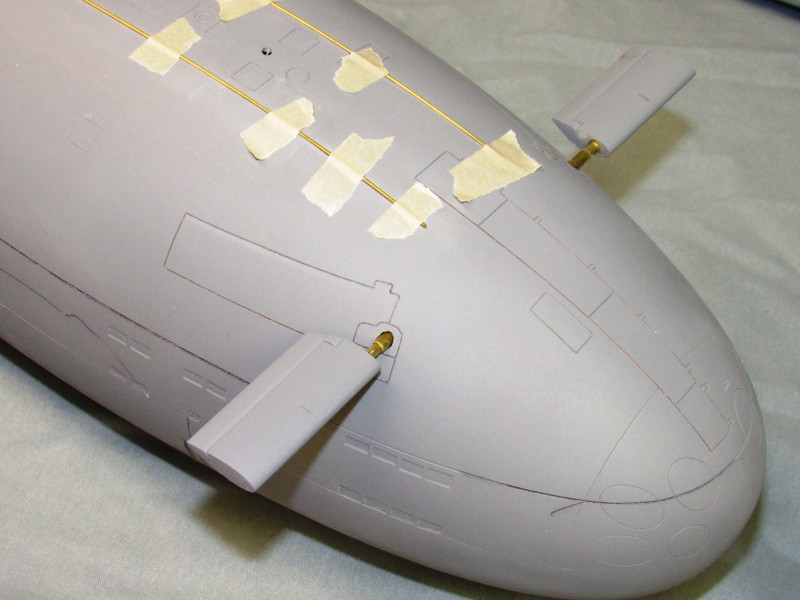

And Scott you are rising star in that listing after I saw the bowplanes you did on the beluga.

Both of you are killing me.

grtz,

Bart

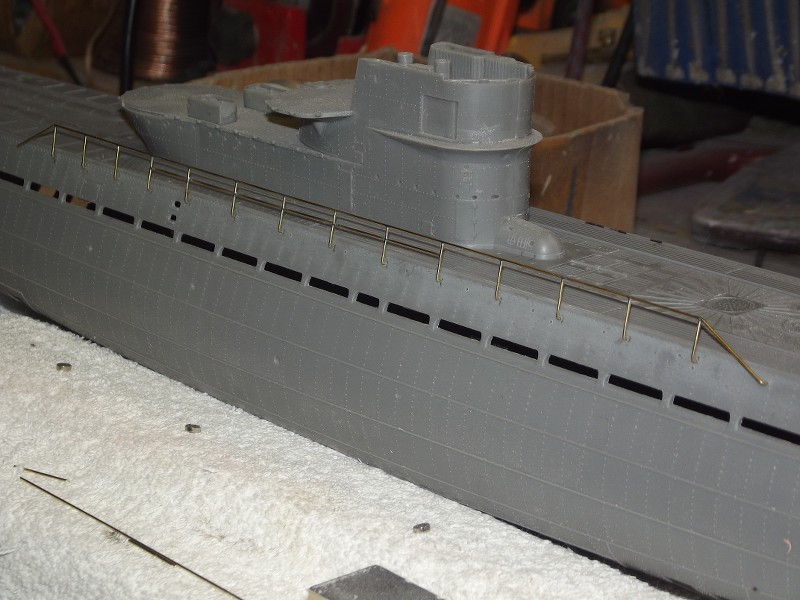

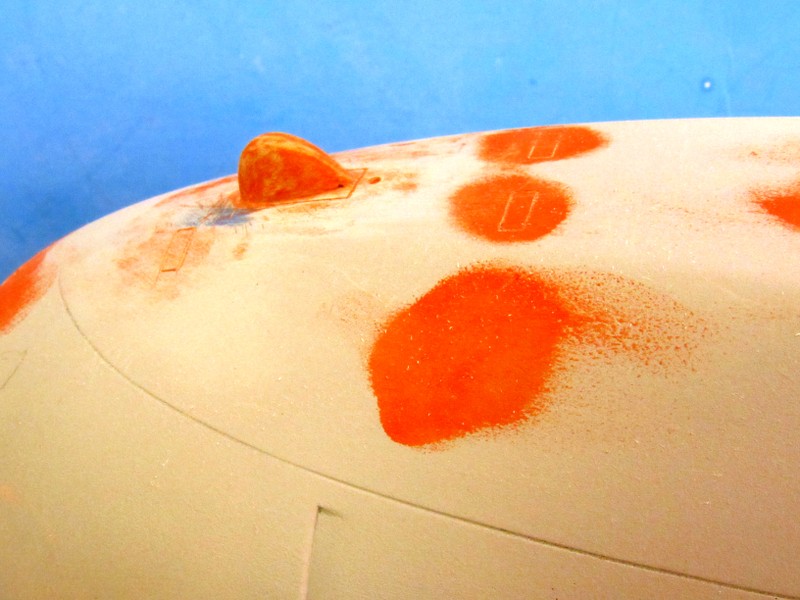

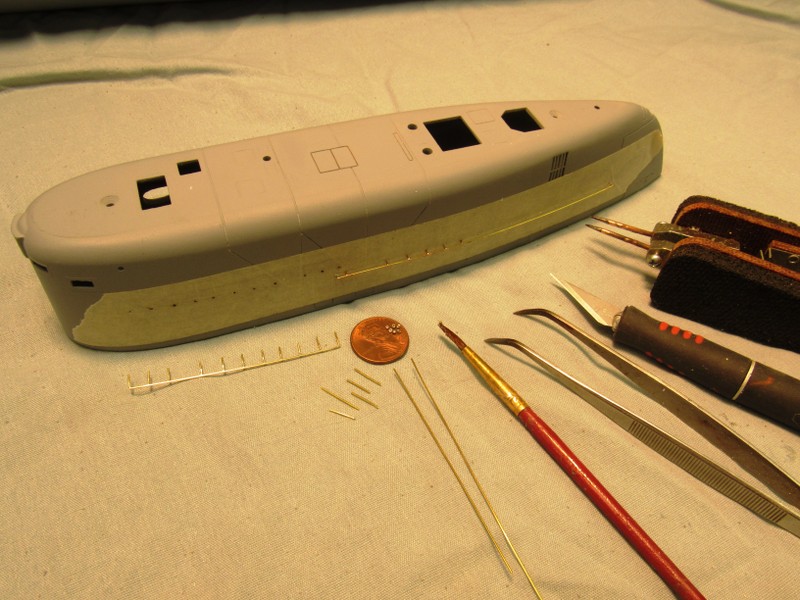

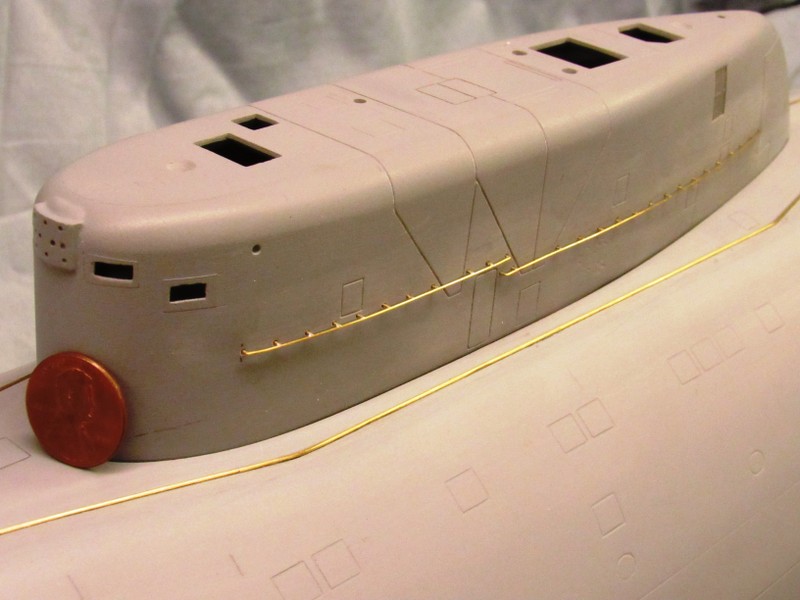

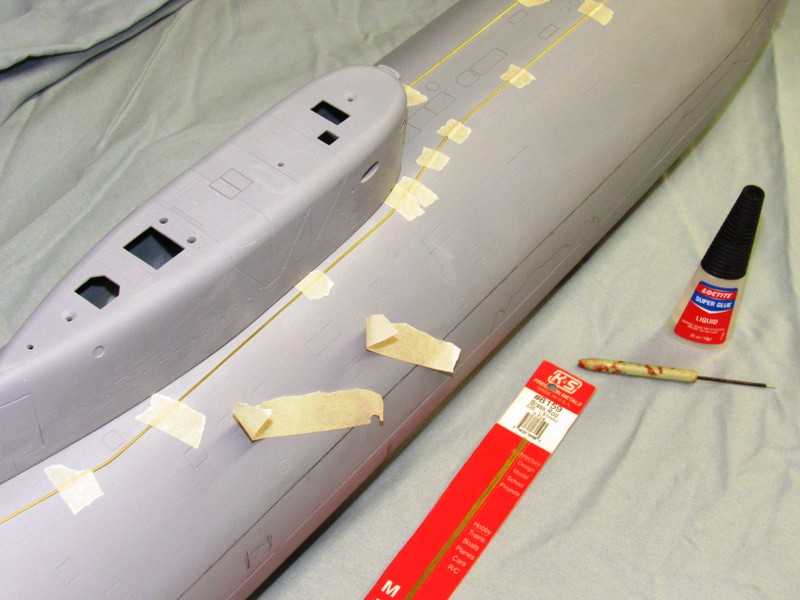

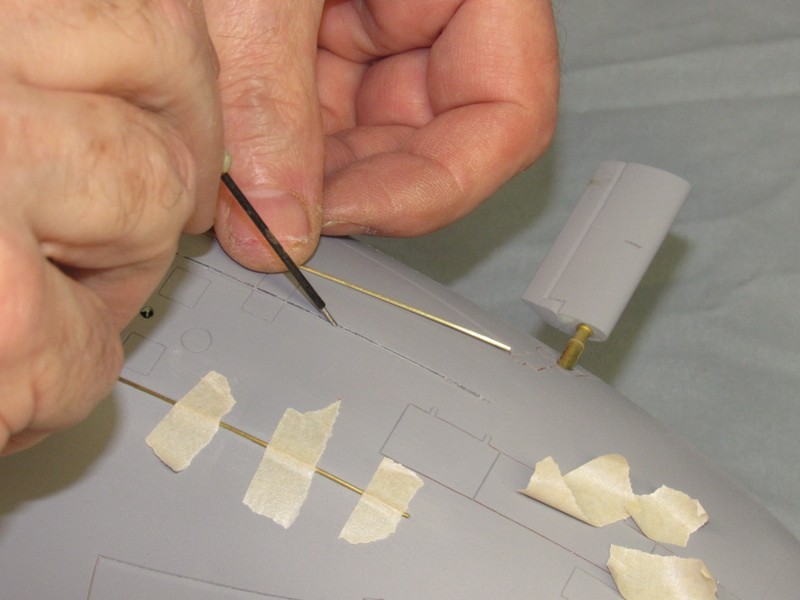

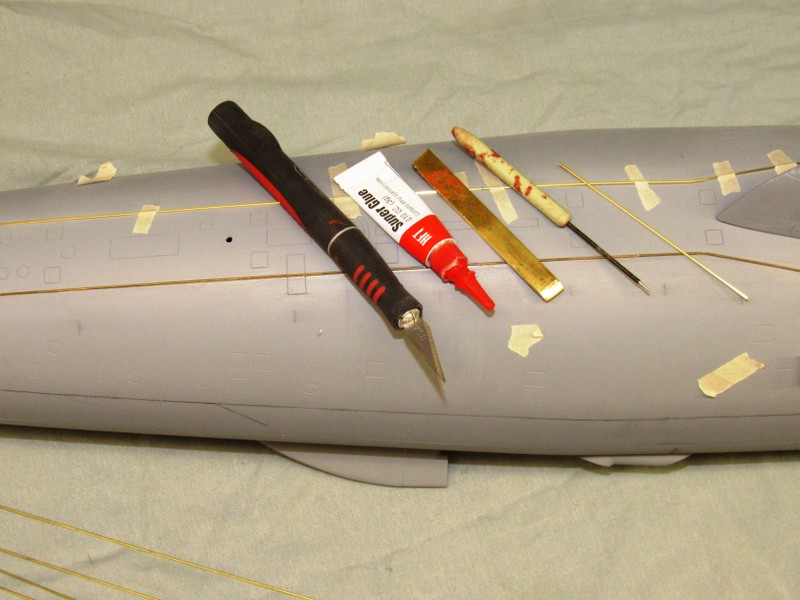

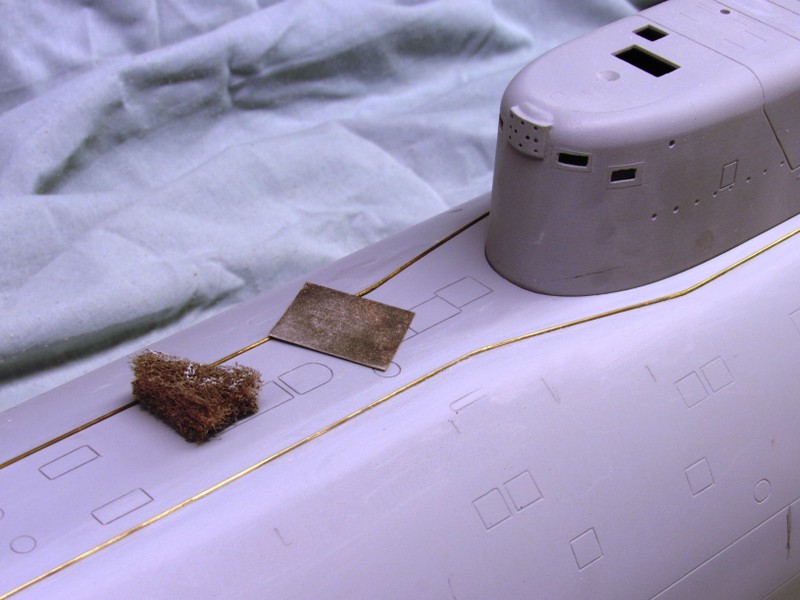

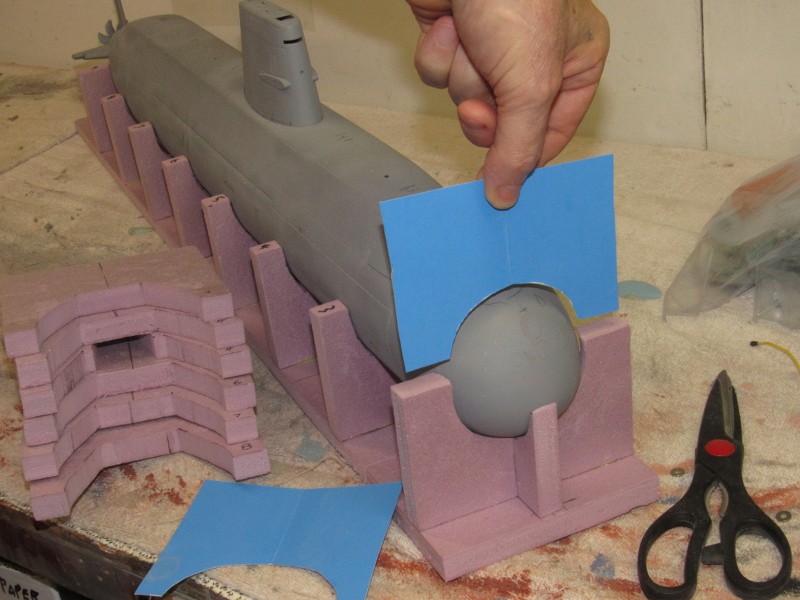

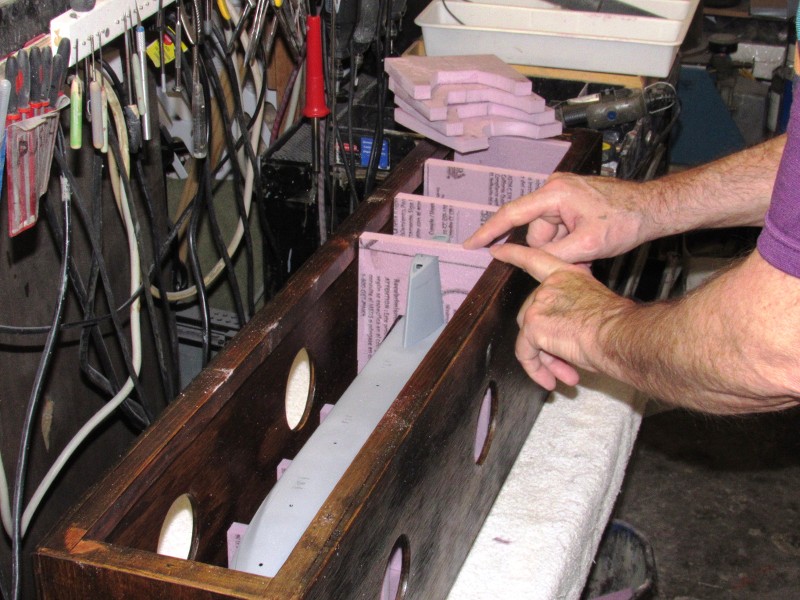

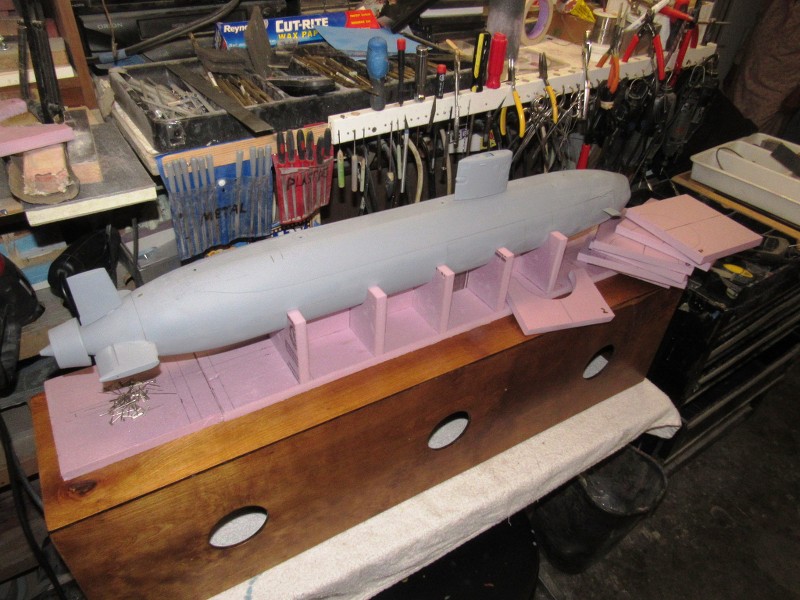

Assembling several Small World Models 1/96 submarine kits

Collapse

X

-

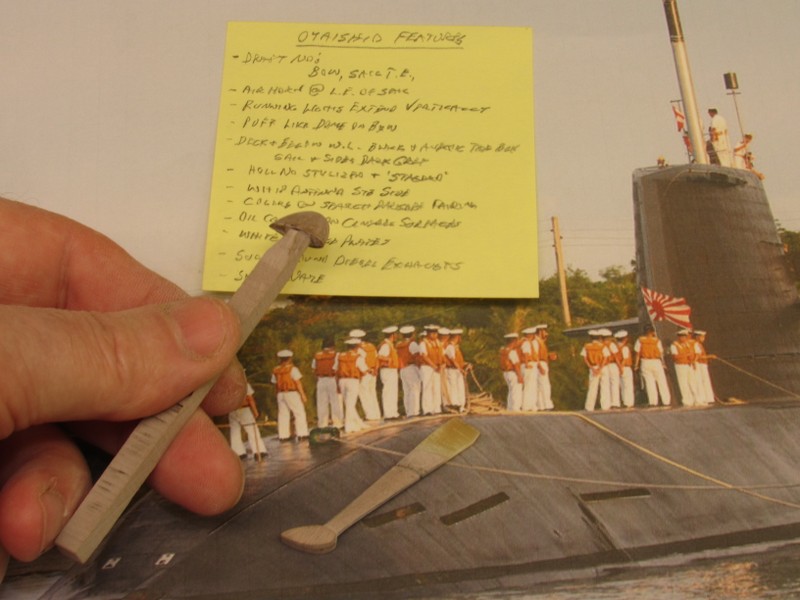

Yeah. Shortly after posting that shot I thought of Bart too. How I'll have to suffer his scorn and indignation about not making them practical.

Suck it, Bart! You perfectionist, you!

What's with the European's anyway -- what a bunch of rivet-counting, over the top, Brainiac engineers! (and crazy good at this game, I might add).

Kevin Rimrodt will also be riding my ass -- he made a practical VG rudder for one of his old projects. He'll be waving it in my face before this thread is finished.

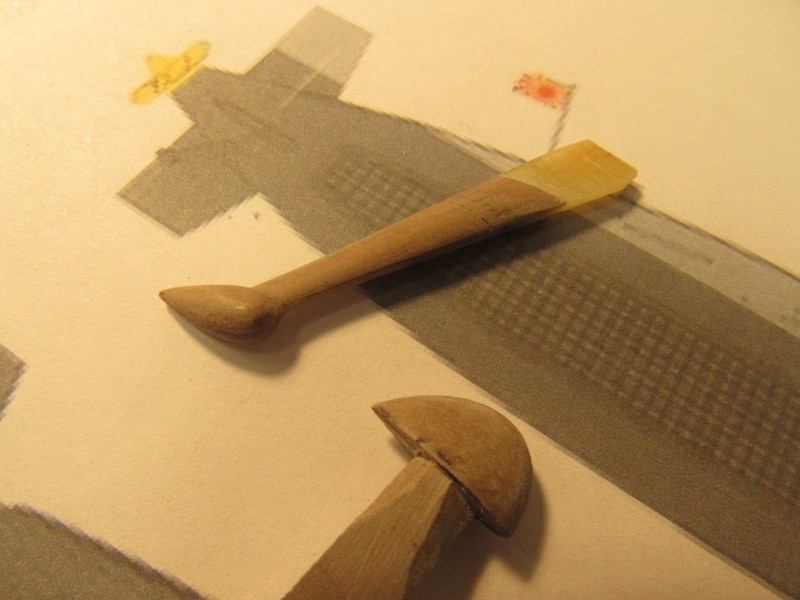

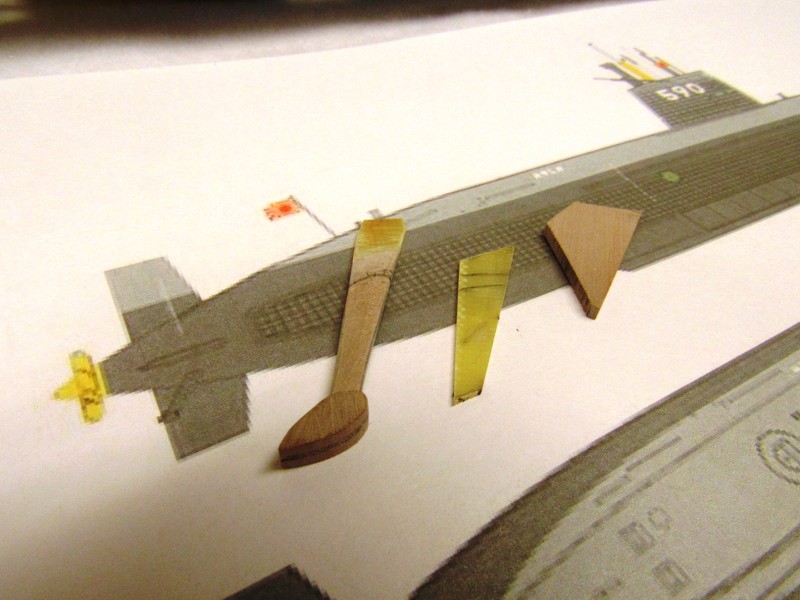

OK!! I don't have time to hinge and make the flap function practical. Sue me! I only have a few months to get these boats ready for the North Carolina 1/96 fleet-run! But, at a later date, with some time on my hands, I might indeed make the bow plane flaps work.

... and thank you so much for ****ing me off before the morning coffee. ****!

David

Leave a comment:

-

Hey. I just noticed the Becker flap on those foreplanes. Your thoughts? (Keep in mind that BART is reading this post too!!!)Leave a comment:

-

If funds are tight and youíre reasonably comfortable with electrics, you can build a decent resistance soldering rig for next to nothing.

Donít envy your task with all that scribing, still a weak area for me, I find any scribing work seems to take forever, redoing lines that are a bit too deep or a bit too wide etc. Thankfully most subjects that interest me seem to have only a modest amount!Leave a comment:

-

David,

i feel like a kid at Christmas time, circling all the toys I want from the sears catalog. However, wanting champagne on a beer bubget gets in the way!Leave a comment:

-

Thanks for the link, Tom. I highly recommend the Beauty brand. Robust, reliable, and can be dialed in to any heat suitable for the job at hand.

Cheap ******* that I am, I've borrowed this particular unit from my running mate, Kevin Rimrodt, who's big on brass railroad stuff -- what he bought the unit for.

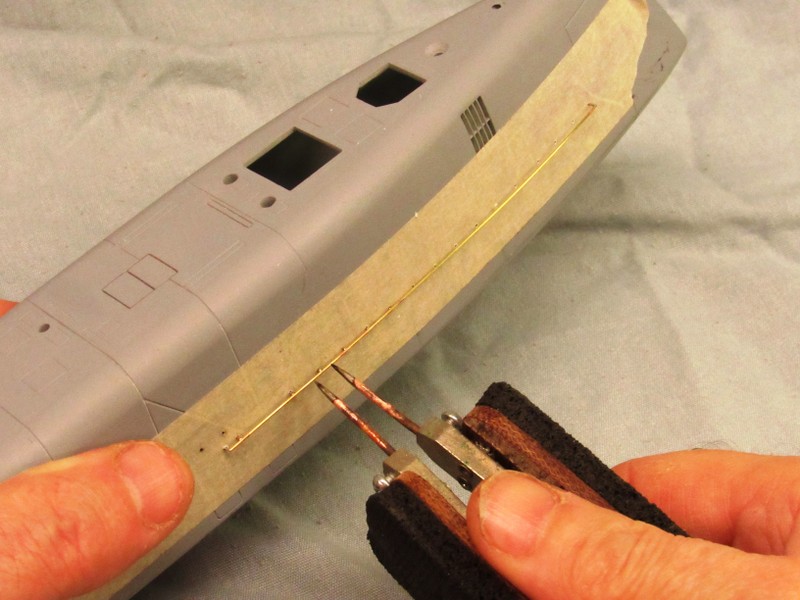

This form of soldering is perfect if you have to hang the brass off easily melted structures (styrene, ABS, Lexan, Acrylic, polyurethane resin, etc.) -- the pinpoint solder flow limits propagation of heat that would otherwise destroy the supporting structure.

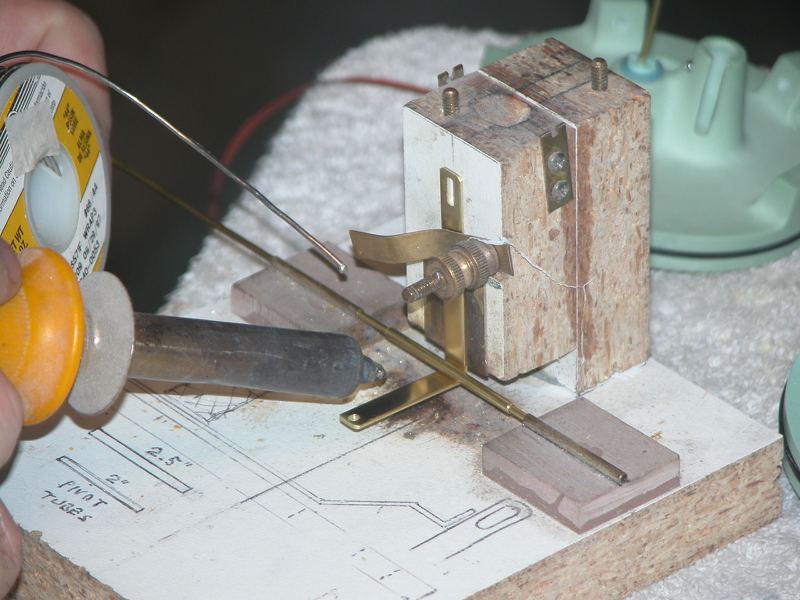

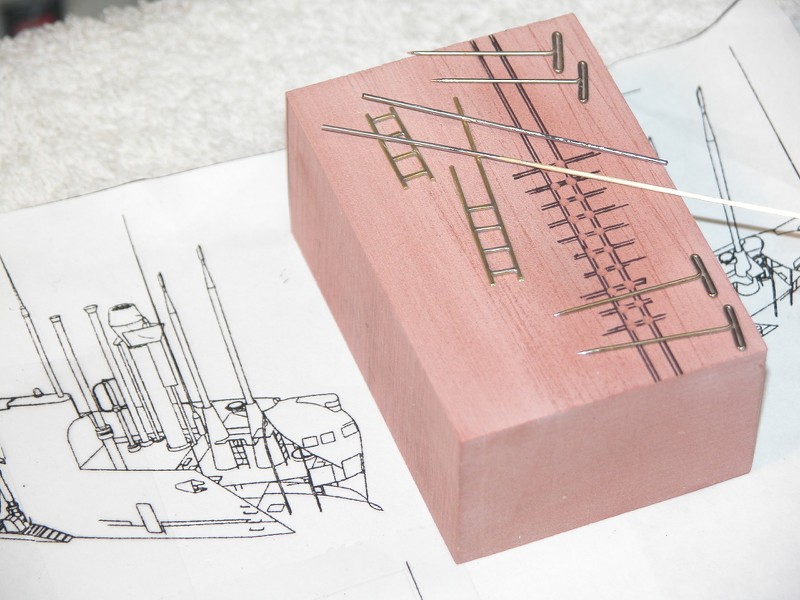

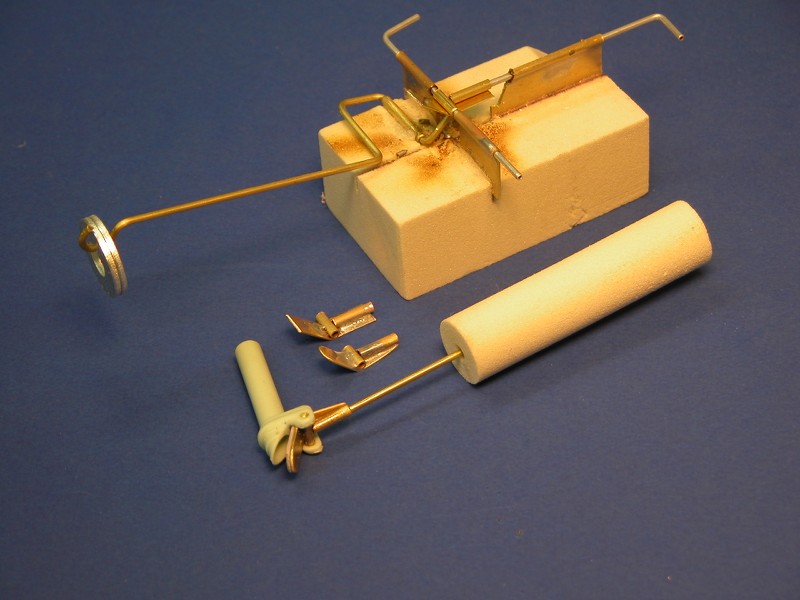

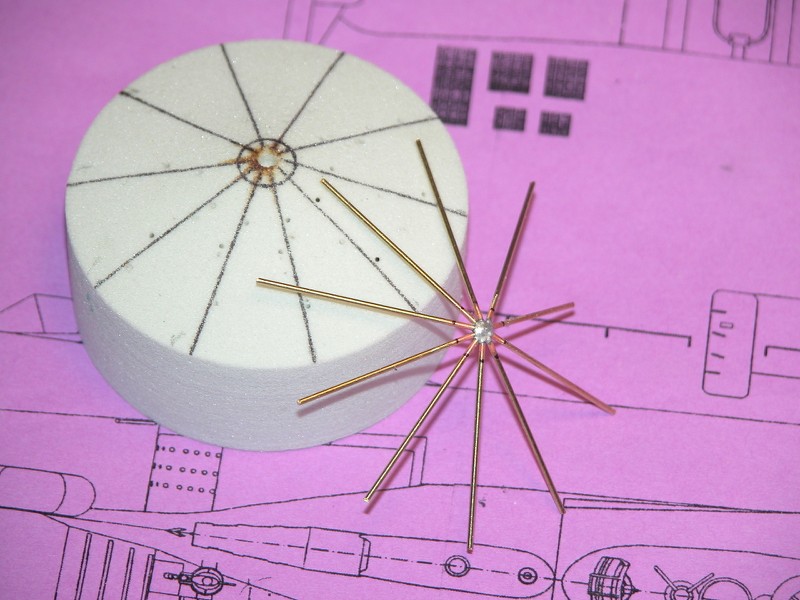

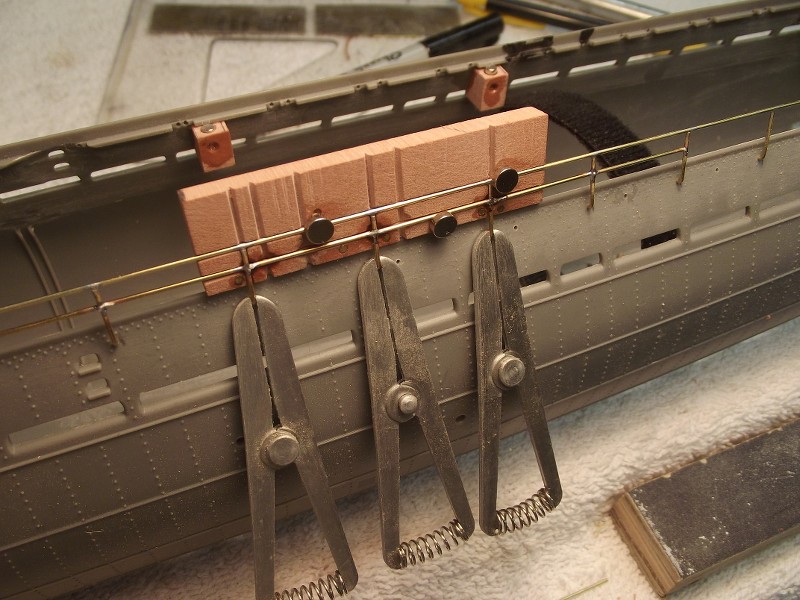

With this ability to solder items in place, you don't have to go through all the trouble of making and setting up a 'soldering jig/fixture'. Like these horror shows:

Sure, you can use heat-sinks, with a traditional soldering iron, but you have to work quickly and carefully -- a pain in the ass.

David

Leave a comment:

-

I too have been wanting to get a resistance soldering tool.

MicroMark sells their brand as well as American Beauty (https://www.micromark.com/mini-power...ring-equipment)

Leave a comment:

-

This is simply outstanding - and yes, I want one, NOW! I also want one of those neat two pronged soldering irons. Given the length of my Honey-Do list the chances of geeing either right now are about as good as being hit by a re-entering space turd.Leave a comment:

Leave a comment: