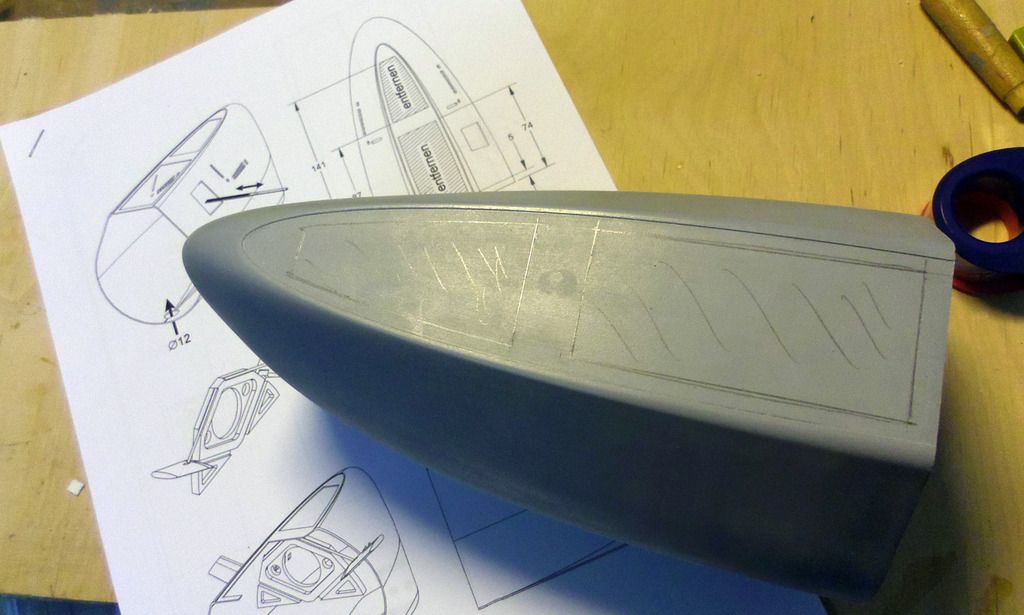

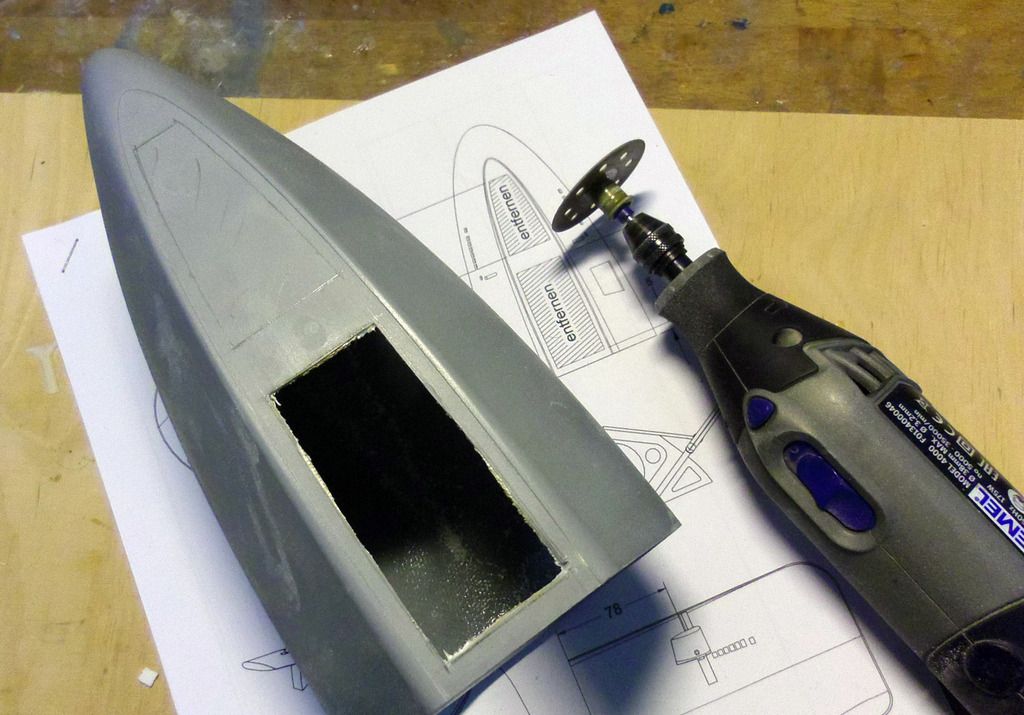

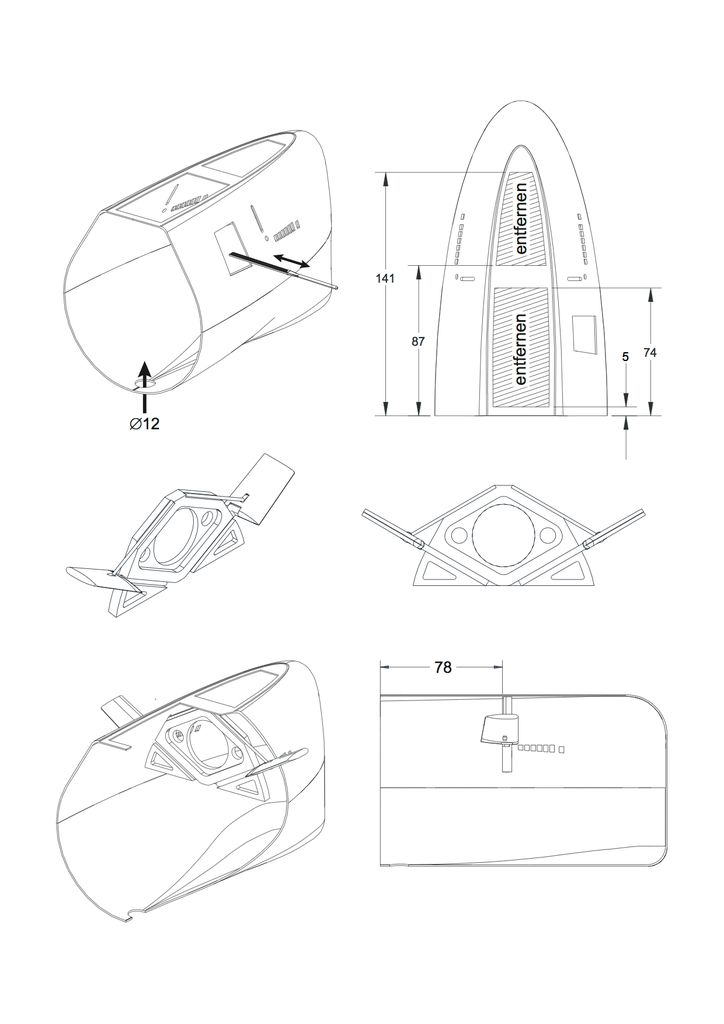

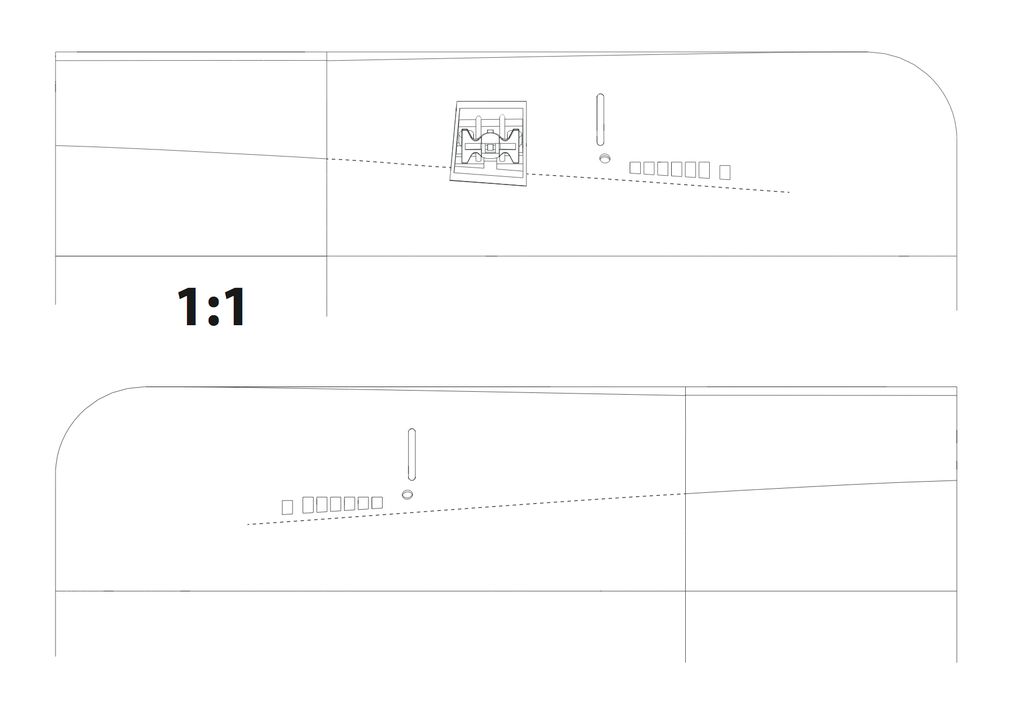

Mark the deck openings, roughly cut them with the diamond wheel and the file it to end dimensions:

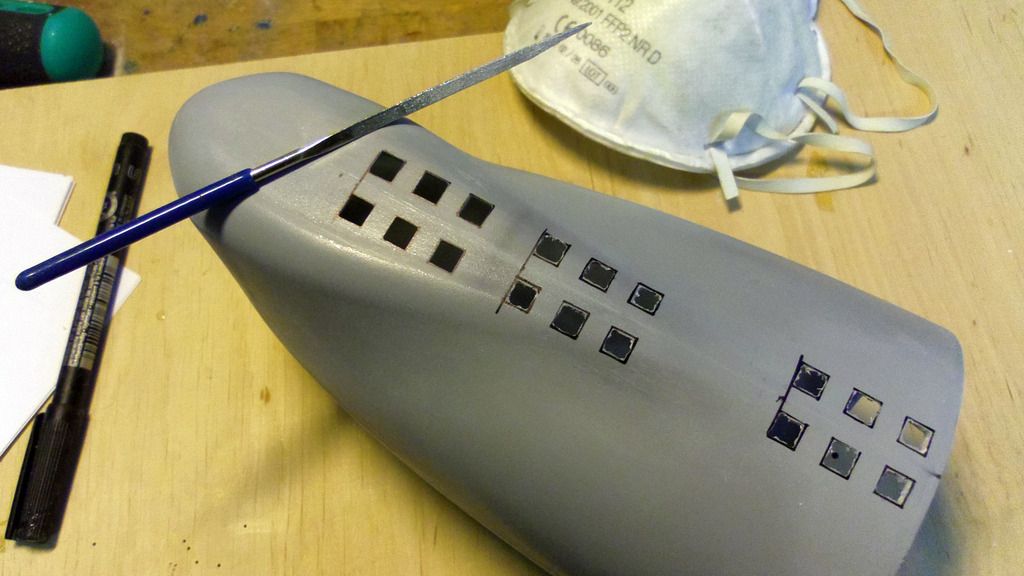

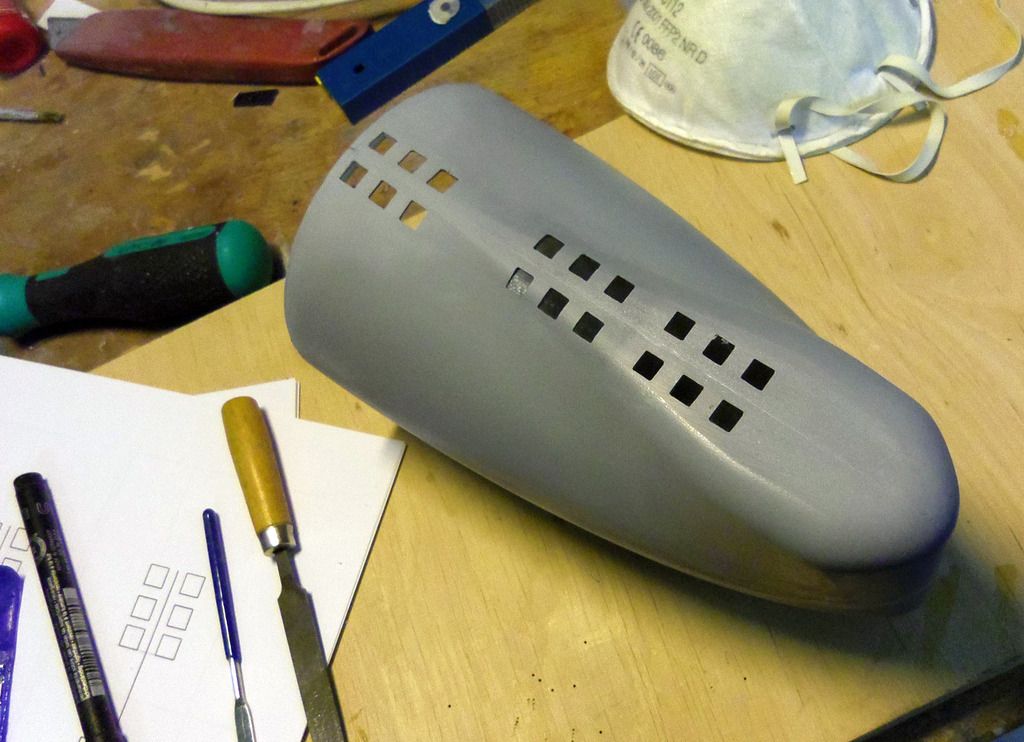

I decided to make the limber holes on the lower side closer tot he original (in contrast to the 12 mm hole depicted in the manual). For marking I made a styrene stencil. Drill the holes out with a 1 mm drill and file them to their final shape using a diamond file.

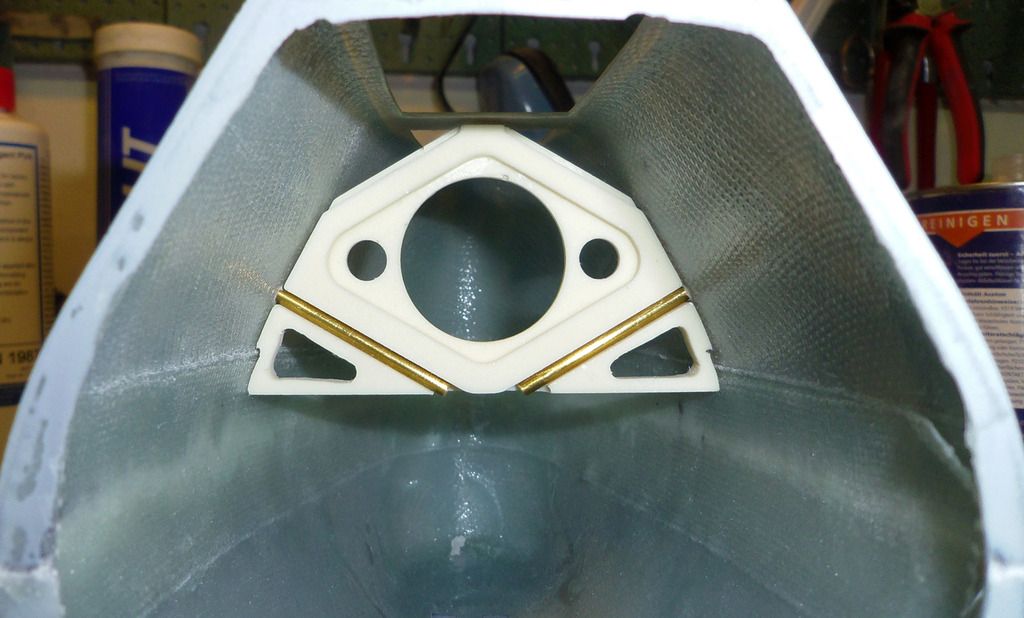

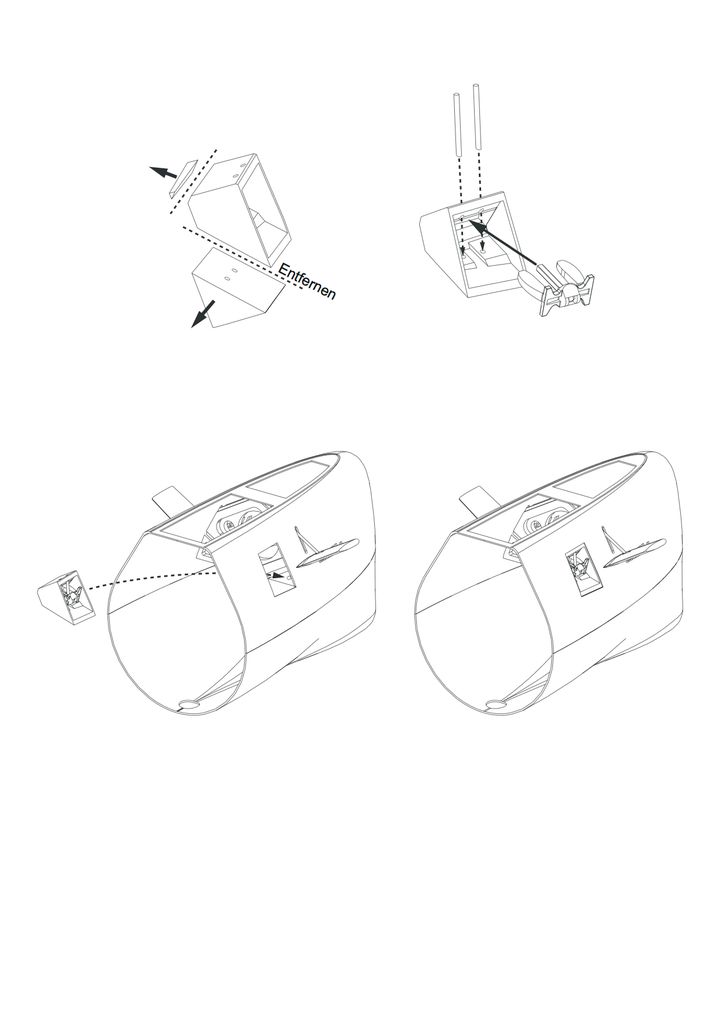

Mark the position oft he bow plane shaft. Here precision is mandatory as precisely positioned shafts make the assembly oft he mount absolutely easy. If everything fits, it’s just a snap together job. Note that the mount was adjusted to the inner contour oft he hull near the seam:

Leave a comment: